- Investigation into susceptibility of coals to spontaneous combustion

- according to PN-93/G-04558 standard

- using the calorimetric method

- Determination of critical conditions for spontaneous combustion of coal in the seam

- Development of a model of gas emission from the heated fragment of coal deposit

- Monitoring of fire hazard level in coal mines based on the precise chromatographic analysis (trace content of carbon monoxide, ethylene, propylene, acetylene and hydrogen and oxygen isotopes) of gas samples together with a current risk assessment

- Prediction of fire hazard in mines together with a risk assessment

- Monitoring of the process of fire suppression and cooling of heated coal mass in sealed off workings based on the precise chromatographic analysis of gas samples

- Determination of conditions for safe opening and ventilation of the workings sealed off due to fire hazard

- Elaboration of the principles for effective fire prevention:

- determination of minimum longwall advance on grounds of fire hazard

- selection of an inert gas

- selection of means that limit air flow through the gobs

- elaboration of principles for prevention based on the use of inhibitors of spontaneous combustion process

- Selection of the equipment and measures necessary for extinguishing fires

- Extinguishing of underground fires by means of active and passive methods

- Investigation into spontaneous combustion of various materials

- Organization and completion of equipment for laboratories performing research relating to:

- early detection of endogenous fires based on the trace content of selected gases in air samples

- susceptibility of coals to spontaneous combustion

- Determining the rules for fire detection in tunnels

Since 1998 we have been accredited by the Polish Centre for Accreditation (Accreditation Certificate AB 005).

The scope of research and expertise:

- verification of hard coal resources, taking into account the factors that are harmful to the environment;

- assessment of hard coal resources for power and coking purposes according to Polish and international standards (JORC);

- modeling of hard coal deposits by means of software (Minescape);

- methane resource assessment of coal deposits (CCM, CBM and AMM) using ECLIPSE simulators;

- assessment of geological conditions of methane occurrence in coal deposits as a main and accompanying mineral;

- elaboration of numerical models of deposits (PETREL);

- elaboration of geological documentation for deposits of hard coal and methane;

- elaboration of Projects concerning Coal and Methane Deposit Management;

- elaboration of Projects concerning geological works;

- testing of the migration of mine gases on the surface of the liquidated mines (ECOPROBE);

- tests on the propagation of gases to the geological environment using computer modelling (TOUGH);

- assessment of geothermal potentials and the use of geothermal waters;

- assessment, analysis and selection of areas of geological CO2 storage;

- model and simulation tests of CO2 injection and reactivity using a TOUGH simulator.

The scope of research and expertise:

- analysis of seismicity in the Upper Silesian Coal Basin based on the registrations of the Upper Silesian Seismological Network of the Central Mining Institute;

- studies on the mechanisms of rock-bursts epicentres and the parameters of their source in terms of the evaluation of seismic hazard;

- calibration of the measuring channels of the seismologic and seismoacoustics equipment;

- seismological network design

- seismoacoustic observation of the longwall panel in mines;

- design and production of seismological equipment for underground mines (Seismic Observation System – SOS GIG) along with the mining seismic events analysis software MULTILOK and SEJSGRAM;

- production of mobile intrinsically safe probes for vibration measurement in underground mines (DLM, DLM-PPV);

- production of the seismoacoustic apparatus PSSP (WAS -96/ RMS method);

- seismic tomography to identify geological disorders in coal seams (faults, washouts);

- passive tomography - reconstruction of the velocity field of seismic waves on the basis of the recorded rock mass tremors by the mines’ seismological networks - in order to assess the seismic hazard from layers prone to bursting;

- evaluation of seismic and burst hazard in mining excavation using the seismological and seismoacoustic methods;

- forecasting of seismic hazard basis on seismoacoustic and seismological observations;

- evaluation of the seismic effect of blasting works in underground and open-pit mines (quarries) and from other seismic vibration;

- forecasting the influence of mining tremors on buildings and the surface environment, including assessments of the effects of vibrations using the Mining Seismic Intensity Scale GSIS-2017;

- design and production of seismometric apparatous AMAX-GSIS for seismic intensity monitoring, with software for interpretation according to the GSIS-2017 scale.

The scope of research and expertise:

- geophysical and geological work documentation and projects for the purpose of diagnosing the geological-engineering and geotechnical conditions;

- reviews and expert opinions on the construction suitability+of post-mining areas;

- research and reviews for assessing post-mining hazards;

- research and assessment of the hazard of mass movements (hollows, landslides, karst);

- research and projects on the conditioning of the construction of areas altered by mining activities;

- research for the purposes of soil, land and groundwater pollution diagnosis;

- research for the purposes of diagnosing geotechnical conditions and leaks in land and concrete hydro-technical buildings;

- non-destructive testing for the purposes of diagnosing the structure and technical condition of the building;

- research for the purposes of diagnosing the thermal state of coal production waste dumps.

- testing of steel ropes, and new rope solutions;

- rope selection;

- research on the control and certification examinations of construction elements of transport equipment including mining link chains;

- certification testing of construction elements and the

- power equipment in accordance with the standard PN-EN 61284 and of wires, CEI IEC 62219:2002, PN-IEC 1089:1994, PN-EN 50182:2002, IEC 62420:2008, PN-EN 60889,:2002, PN-EN 50189:2002, PN-EN 60889:2002, PN-EN 50183:2002;

- geometric measurements of excavation shafts and constructions using laser scanning;

- tests of cable railways.

- station tests of door-frames of roadway supports;

- examination of the accessories of roadway supports (shackles, struts, welded nets, cladding, support footings, etc.);

- tests of stands and hydraulic servomotor (statics and dynamics);

- testing of friction prop;

- tests of valves and valve blocks;

- tests of roof-bars and bases;

- tests of high pressure, hydraulic wires and hoses;

- tests of idlers;

- tests of large-diameter pipes made of any material (tightness of connection, peripheral stiffness);

- strength tests of elastomeric bearings (test of the non-dilatational deformation module, shear adhesion test and compression test);

- testing of structural components at dynamic loads (rail buffers, chains, etc.).

CALIBRATION:

Calibration of mechanical vibration measuring instruments within the Scope of Accreditation No AP 006 granted by PCA:

- calibration of vibration transducers in accordance with the ISO 16063-21 standard in the frequency range of 0.5 Hz - 10 kHz,

- calibration of vibrometers - measuring instrumentation of human response to vibration in accordance with the PN-EN ISO 8041-1:2017 standard,

- calibration of vibration calibrators in the frequency range of 15 Hz

-2 kHz, - calibration of machine vibration meters in accordance with the ISO 2954 standard in the frequency range of 10 Hz

-2 kHz;

Calibration of instruments for acoustic measurements within the Scope of Accreditation No AP 006 granted by PCA:

- calibration of sound level meters in accordance with the PN-EN 60651 and PN-EN 60804 standards,

- calibration of sound level meters in accordance with the PN-EN 61672 standard,

- calibration of sound calibrators - comparative method in accordance with the PN-EN 60942 standard,

- calibration of sound calibrators - insert voltage calibration method in accordance with the PN-EN 60942 standard,

- calibration of octave and 1/3 octave band filters in accordance with the PN-EN 61260 standard,

- calibration of measurement microphones using the LS class calibrator method and insert voltage calibration method - in accordance with the PNEN 61094 standard;

Calibration of vibration measuring instruments beyond the scope of the PCA accreditation:

- calibration of impact hammers according to the manufacturer’s instructions in the frequency range 10 Hz - 10 kHz,

- calibration of laser vibrometers in accordance with the ISO 16063 standard in the frequency range 0.5 Hz - 10 kHz,

- calibration of palesthesiometer (measuring instruments for vibrotactitle perception thresholds) in accordance with the ISO 13091-1: 2001: 2006 standard,

- calibration of signal recorders / analysers / signal conditioning systems.

Summary of the offered calibration services is presented in the Tables below:

Calibration within the Scope of Accreditation No AP 006

Object | Norm | Frequency range |

Vibration transducers (acceleration and velocity) | ISO 16063-21:2003 | 0,5 Hz – 10 kHz |

Vibrometers - measuring instrumentation of human response to vibration | PN-EN ISO 8041-1:2017 | 2 Hz – 800 Hz |

Vibration calibrators | ISO 16063-21:2003 | 15 Hz ÷ 2 kHz |

Machine vibration meters | ISO 2954:2012 | 10 Hz – 2 kHz |

Measuring microphones | PN-EN 61094-6:2005 | 20 Hz – 20 kHz |

Sound calibrators using the standard microphone method | PN-EN 60942:2005 | 250 Hz, 1 kHz |

Comparative sound calibrators | PN-EN 60942:2005 | 250 Hz, 1 kHz |

Sound level meters | PN-EN 60654:2002 (U) PN-EN 60804:2002 (U) PN-EN 61672-3:2007 PN-E 61672-3:2014-03 | 20 Hz – 20 kHz |

Band filters with octave width or part of an octave | PN-EN 61260:2000 | 20 Hz – 20 kHz |

Calibration outside the Scope of Accreditation No AP 006

Object | Norm | Frequency range |

|---|---|---|

Modal hammers | As indicated by the manufacturer | 10 Hz – 10 kHz According to the data manufacturers' catalogues |

Laser vibrometers | ISO 16063-41:2011 | 0,5 Hz – 15 kHz |

Signal recorders Analyzers Signal conditioning systems e.g. SCADAS, PULSE, Vibration Research, ADRE | ISO 2954:2012 | 0,5 Hz – 15 kHz |

RESEARCH:

Acoustics

- indoor and outdoor environmental noise - the influence of traffic and/or industrial noise on open land areas –within the Scope of Accreditation No AB 005 granted by PCA,

- digital noise maps preparation using GIS and GPS technology –within the Scope of Accreditation No AB 005 granted by PCA,

- environmental impact assessment of industrial sites, transport routes, public utility facilities and others concerning vibroacoustic hazards –within the Scope of Accreditation No AB 005 granted by PCA,

- vibroacoustic forecasting for investments and sites undergoing modernisation at various stages –within the Scope of Accreditation No AB 005 granted by PCA,

- in situ testing of the screening efficiency in areas protected by acoustic barriers

-within the Scope of Accreditation No AB 005 granted by PCA, - tests of the impact of noise caused by sources located indoor and outdoor on people staying in residential, public and others buildings,

- determination of sound power levels and sound energy levels of noise sources using sound pressure - engineering methods for an essentially free field and survey method using an enveloping measurement surface, over a reflecting plane in accordance with PN-EN ISO 3744: 2011 and PN-EN ISO 3746: 2011 standards - within the Scope of Accreditation No AB 005 granted by PCA,

- testing of noise emission of machines at their place of operation.

Vibration

- testing of the impact of mechanical vibrations transferred through the ground on the construction of buildings and other structures in accordance with standard PN-B-02170:2016 - within the Scope of Accreditation No AB 005 granted by PCA,

- diagnosis of the technical state of buildings and engineering structures using the modal and wavelet analysis,

- tests of the impact of mechanical vibration on people in buildings in accordance with the PN-B-02171:2017 standard - within the Scope of Accreditation No AB 005 granted by PCA,

- quality assessment of rock bolt support systems in coal mines, tunneling and building reinforcement,

- environmental testing of technical objects, devices and apparatus with weight, up to 120 kg using the vibration exciter

-according to standard PN-EN 60068-2-6:2008 - within the Scope of Accreditation No AB 005 granted by PCA, - tests of the resistance of technical objects to vibrations in accordance with the requirements specified by the customer,

- tests of resonant frequencies of technical objects,

- tests of the impact of mechanical vibration on people within the framework of research projects.

Electrostatics

- material, product and equipment tests using standard methods,

- personal protective equipment electrostatic property evaluation,

- electrostatic protection,

- formulating opinions and interpretations based on test results,

- work related to the antistatic treatment of plastics,

- EPA (ESD Protected Area) implementation,

- audits concerning EPAs and electrostatics,

- destructive testing related to electrification,

- tests under a broad range of climatic conditions in a climatic chamber,

- tests of the electrical and electrostatic earthing of installations and facilities.

Thermovision

- tests of the thermal insulation of buildings and heating pipelines;

- tests of the thermal state of industrial waste dumps, especially mining, and coal storage sites;

- tests of the thermal state of machines use in technical, energy and horizontal mining transport equipment;

- human examinations for medical diagnostic purposes;

- early detection of endogenous fires in underground mines using pyrometers;

- high-current power connector efficiency tests.

Meteorological station www.meteo.gig

Presentation of current weather conditions from the meteorological station located within the Central Mining Institute.

- assessment of the state of associated hazards,

- selection of prevention for the conduct of work in the conditions of the associated hazards,

- ad hoc consultations on the issues of associated hazards,

- the forecast and assessment of seismic hazard and of bursts of mining workings,

- rock mass quality assessment in terms of geomechanics and rock burst hazards with the application of empirical-analytical index methods,

- rock mass burst tendency assessment,

- analytical evaluation of stresses in the seam and surrounding rocks,

- analysis of the eligibility of seams(deposits) or their parts to the respective degrees of rock burst hazard,

- development of complex (technical) projects for the exploitation of rockburst-threatened seams,

- assessment of the risk of conducting mining works in rock burst hazard conditions,

- selection of immediate (active) and long-term (passive) rock burst prevention methods,

- designing directional hydraulic fracturing and directional blast-enhanced fracturing as methods for rock blast prevention and working protection against excess static loads in hard coal and copper ore mines,

- consultations on the conduct of works under the conditions of particular rock burst hazards,

- techniques and technologies for the modification of the properties of minerals (coal, metal ores, raw rock materials) and of rock mass for improving the safety and efficiency of operation (e.g. fracturing with hydraulic and blasting techniques),

- coal deposit destressing by means of water jet cutting in order to decrease the state of stress and increase gas permeability,

- designation of basic geo-mechanical rock mass characteristics (component states of primary and pseudo-primary stresses),

- determining basic rock mass geomechanical properties (components of geostatic stresses and combined geostatic and mining-induced stresses) using hydraulic methods (microfrac) and the overcoring method,

- engineering techniques and technologies to secure the protected underground environment (caves, historic objects, etc.),

- examination of the range of the fracture zone of a rock mass surrounding a working using the aerometric method,

- in situ testing of the permeability of coal deposits and rock strata using the hydraulic method (slug test).

- testing and assessment of the burst tendency of coal and gangue;

- assessment of rock mass inclination for bursting, considering geo-mechanical rock properties and Energy properties as well as the scale effect by using the rock mass bursting tendency index, WTG, the rock mass kinetic energy index WEk and the Geological Strength Index (GSI);

- assessment of the tendency of multi-layered carboniferous rock mass to bursting, through the application of a geological- geochemical system of the method assessing the rock mass inclination for bursting GEO;

- assessment of rock mass inclination for bursting in thE frontier areas of active mines, in which the excavations are threatened by rock bursts, and of liquidated mines, by flooding due to secondary rock mass watering in active mines as a result of conducting this process;

- assessment of the impact of rock mass structural defects and the impact of rock mass destruction caused by mining operation on the geo-mechanical properties of carboniferous rocks and on the inclination of the rock mass for bursting;

- ad hoc consultations on the issues of rock and rock mass inclinations for bursting.

Physical and technological properties of rock and rock mass:

- laboratory tests of geo-mechanical properties, including the properties of surrounding minerals and rock resources under different stress conditions and humidity, states, different deformation and loading velocities, as well as tests of selected physical and technological parameters;

- studies of rock deformability in a complex stress state and studies of the deformation process of loaded rocks in a post- critical state;

- studies of appropriate deformation energy in the proces of rock destruction (loading);

- in situ studies with a borehole penetrometer of strength parameters of rocks in drilling holes along with classifying the quality of the deck roof and the assessment of rocK mass fissuring;

- testing and assessment of the stability of the caving ruble as the roof of the underground workings;

- non-destructive testing of the strength of the rock mass using the rebound number method;

- assessment of the quality of the rock mass, on the basis of the classification of geotechnical rock massifs;

- geo-statistical analysis of the rock mass geo-mechanical parameters - development of the forecast of geo-mechanical parameters’ value distribution along with the estimation of its accuracy in the areas of the planned operation;

- development of geological documentation of drilling holes for the purposes of mineral reconnaissance and obtaining by the entrepreneur the concession for its extraction;

- preparing documentation within the scope of assessing the propensity of rocks and the rock mass for generating rock bursts, including rock burst hazard assessment in workings by means of geological and geomechanical criteria;

- preparing documentation within the scope of assessing rock properties and rock mass quality for the purposes of planning and conducting mineral resource deposit extraction;

- preparing documentation within the scope of assessing the properties and usability of building materials, post-mining waste, resins and bonding agents for the purposes of mining, geoengineering, building engineering and environmental protection;

- preparing documentation within the scope of assessing the influence of temperature on the behaviour of rock under static and dynamic loads for the purposes of unconventional methods of mineral resource deposit extraction;

- documenting the geological-engineering conditions for the purposes of the liquidation of mines;

- evaluation of the behaviour of rocks at great depths and drawing conclusions for the purposes of designing the safe operation of various deposits of mineral resources;

- assessment of the occurrence of natural hazards in the rock mass, these being mainly geo-mechanical and water hazards, especially in mines with operations near bodies ofwater created in gobs of liquidated mines;

- interpretation of geological and geo-mechanical conditions within water hazard sources;

- determination of the pillars of security and security zones, pillars of technology in the pillar-chambered system;

- planning, in terms of the liquidation of mines, of the decommissioning process and the assessment of security in active mines related to the water from decommissioned mines;

- assessment of the possibility of the occurrence of certain natural hazards in the limit zones of active mines in connection with the flooded excavations of the liquidated mines;

- assessment of the possibility to apply the results of the laboratory tests on the changes of the properties of rocks under the influence of temperature to improve numerical models as tools to resolve the problems in mining and geoengineering practice, e.g. forecasting the behaviour of the rock mass as a result of the underground coal gasification process conducted in it.

- testing and utility evaluation of hard rocks, including post-mining waste, for the purposes of geoengineering, mining(liquidation of mining shafts) and construction (general,road, underground, hydro-technical);

- strength test of concrete and concrete structures by the rebound number method;

- testing and evaluation of permeability and frost resistance of concrete;

- testing and evaluation of the quality of aggregates, crushed stone, slate, precast concrete flooring elements, ceramic products, organic and mineral-organic resins as well as mineral binders.

- testing of high and low temperature impact on the behaviour of the rocks under static and dynamic load, in the total range of their deformation;

- assessment of the quality of the rock treated with the temperature for unconventional methods of deposit extraction and geoengineering.

- Determination of methane content using direct method.

Coal degassing stand using the MOD-2

- Desorption tests using United States Bureau of Mines (USBM) method.

Tests include:

- Determination of lost gas, desorbing gas and residual gas,

- Determination of the composition of desorbing and residual gas by gas chromatography,

- Determination of final methane content.

Stand for desorption tests (USMB)

- Determination of physical and chemical parameters of solid fuels:

- ash content (A),

- expiring moisture (Wex),

- hygroscopic moisture (Wh),

- moisture in the analitical sample (Wa),

- total moisture (Wt)

- voltalite matter (Vdaf),

- density by helium pycnometry (dr). - Research on the desorption of methane from coal under variable hydrostatic pressure conditions.

- Determining coefficient of rocks’ conciseness (fz).

- Chromatographic analysis of mine air: O2, N2, H2, CO2, CO, CH4, C2H6, C2H4.

- Chromatographic analysis of the following gases: O2, N2, H2, CO2, CO, CH4, C2H6, C2H4, C2H2, C3H8, C3H6, n- C4H10.

- Detection of flammable and toxic gases hazardous concentrations: O2, CO2, CO, CH4, H2S, SO2, NO2, NO.

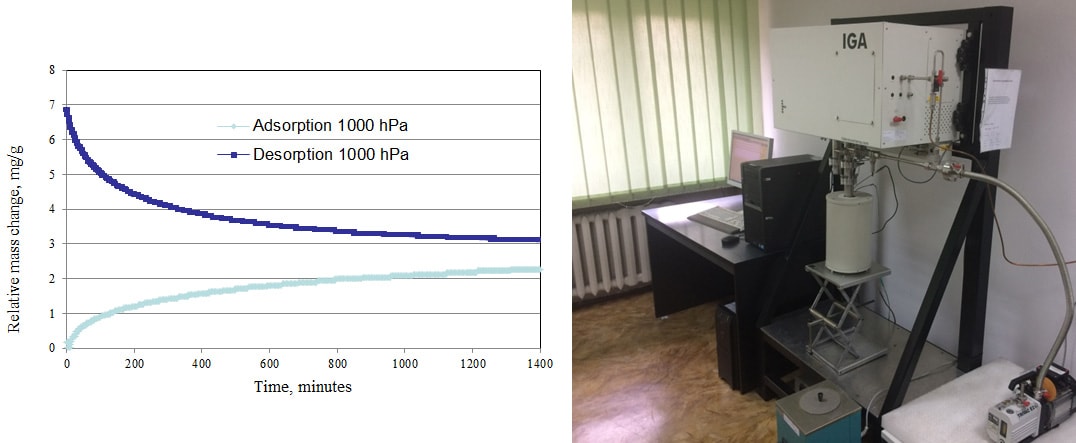

- Determination of sorption parameters:

- effective diffusion coefficient (De),

- sorption capacity (a),

- sorption capacity calculating into daf (adaf),

- sorption half-time (t0,5),

- determination of sorption isotherms based on Langmuir isotherm model.

Methane sorption and desorption changes tests using gravimetric

etting IGA-001 to determine sorption parameters of coal

Laboratory of Air Dustiness Measurements (KD-2.2) is a part of the Group of Testing and Calibration Laboratories of the Central Mining Institute accredited by the Polish Accreditation Centre (PCA) in Warsaw.

Since 1998 Laboratory has been accredited as a calibration laboratory, number of accreditation - AP 006, website: https://www.pca.gov.pl/akredytowane-podmioty/akredytacje-aktywne/laboratoria-wzorcujace/AP%20006,podmiot.html

The accreditation includes calibration of dust samplers and aspirators:

- Barbara 3Adust sampler with flow rate of 4,5 - 5,5 dm3/min,

- personal dust sampler CIP-10 with flow rate 9,8 – 10,2 dm3/min,

- aspirators: SKC, AP 2000Ex, Gilian and others with the flow of 1,7 - 2,4 dm3/min.

The laboratory is also accredited as a testing laboratory, number of accreditation - AB 005, website: https://www.pca.gov.pl/akredytowane-podmioty/akredytacje-aktywne/laboratoria-badawcze/AB%20005,podmiot.html since 2006 in the scope of:

- measurements of dust concentration at workplaces,

- measurements of the dust concentration of the most dust-generating technological process (worst case),

- selection of personal respiratory protection of an employee at his workplace,

- measurement and analysis of respirable fibres in air at workplaces or in an environment,

- measurement and analysis of respirable asbestos fibres in air at workplaces or in an environment,

- analysis of grain size distribution of airborne dust (outside the scope of the accreditation).

The Laboratory also carries out research outside the scope of the accreditation:

- effectiveness and correctness of dust collection equipment with the separate ventilation system of mines built in mine roadways,

- internal and external sprinkler systems installed on the shearers and the heading machines in terms of effectiveness of control of mechanical sparks capable to ignite methane and reduction of airborne dust,

- strength tests of suction and discharge flexible lutes.

Participation in projects:

The Laboratory is a member of the consortium that performs research in the European Project ROCD of the Fund for Coal and Steel (RFCS) “Reduction of risk associated with exposure to coal dust”.

More important research and development activities:

- tests and evaluation of the effectiveness of methane and spark extinguishing generated by shearers and the heading machines in accordance with Polish legal requirements,

- calibration of personal dust samplers CIP-10, Barbara 3A and aspirators in the calibration laboratory (AP 005) in accordance with the procedures accredited by the Polish Centre for Accreditation (PCA) in Warsaw,

- determination of respirable fibres in dust, in accordance with the procedures accredited by the Polish Centre for Accreditation (PCA) in Warsaw,

- quantitative and qualitative microscopic analysis of dust samples for the presence of coke collected in areas where hazardous event happened.

Since 70’s of XX century, risk mitigation and phenomena associated with dusts explosions occurring in all branches of industry except mining industry, are the main research field of Industrial Dust Explosion Laboratory.

The laboratory’s area of activity covers:

Research:

- Measurements if dust explosion characteristic parameters in laboratory and large scale tests

- Verification and calibration of dust explosions models

List of selected publications:

- Dyduch Z., Toman A., Adamus W.: Measurements of turbulence intensity in the standard 1 m3 vessel, Loss Prev. Proc. Ind., 40, 2016, 180-187

- Dyduch Z., Pękalski A.: Methods for more accurate determination of explosion severity parameters, J. Loss Prev. Proc. Ind., 26, 2013, 1002-1007

- Dyduch Z., Skjold T.: An assessment of the laminar burning velocity in dust/air mixtures based on a model for dust explosions in closed 20-litre vessels, Proceedings of the 8th Eighth International Symposium on Hazards, Prevention, and Mitigation of Industrial Explosions, Yokohama 5-10 September 2010

- Dyduch Z., Majcher B.: Ignition of a dust layer by a constant heat flux-heat transport in the layer, J. Loss Prev. Proc. Ind., 19, No. 2-3, 2006

- Lebecki K., Dyduch Z., Fibich A., Śliż J.: Ignition of a dust layer by a constant heat flux, J. Loss Prev. Proc. Ind., 16, No. 4, 2003

- Dyduch Z.: Prosty model propagacji wybuchu w mieszaninie pył-powietrze, Prace Naukowe GIG. Górnictwo i Środowisko, 3, 2004

- Dyduch Z.: Zagrożenie wybuchem pyłu podczas składowania i przetwarzania surowców spożywczych, Ochrona Przeciwpożarowa, 2 (20), 2007

- Dyduch Z.: Szacowanie laminarnej szybkości spalania mieszanin pył-powietrze na podstawie pomiarów ciśnienia w komorze sferycznej, Prace Naukowe GIG. Górnictwo i Środowisko, 4, 2009

- Dyduch Z.: Specyfika zagrożenia wybuchem pyłów przemysłowych, Powder & Bulk, 4, 2009

- Dyduch Z.: Kilka zagadnień związanych z zagrożeniem wybuchem pyłu w instalacjach nawęglania i podawania biomasy, Magazyn Ex, 2012

Commercial service:

Assessment of dust explosion and ignition parameters

In Industrial Dust Explosion Laboratory all standard ignition and explosion parameters are determined according to the European Standards:

- Identification of combustible dust: VDI 2263 and EN ISO/IEC 80079-20-2:2016-05

- Dust explosion characteristic including maximum explosion pressure pmax , maximum rate of pressure rise (dp/dt)maxand deflagration index KSt max: EN 14034-1, EN 14034-2

- Lower explosion limit (LEL): EN 14034-3

- Limiting oxygen concentration (LOC): EN 14034-4

Above mentioned tests can be performed in the standard 1 m3 vessel and in 20-l sphere manufactured by Adolf Kühner AG.

- Minimum ignition temperature of dust cloud (MIT): EN ISO/IEC 80079-20-2:2016-05

- Minimum ignition temperature of dust layer (T5mm): EN ISO/IEC 80079-20-2:2016-05

- Minimum ignition energy of dust/air mixtures (MIE): EN ISO/IEC 80079-20-2:2016-05

- Determination of spontaneous ignition behaviour of dust accumulations (TSI): EN 15188

- Dust layer resistivity (ρ): EN ISO/IEC 80079-20-2:2016-05

Dust explosion risk assessment

- For operating industrial facilities: (1999/92/WE ATEX Users)

- Based on plant design or as-built documentation: (1999/92/WE ATEX Users)

This type of evaluation has been performed for food industry, metallurgical industry, oil industry, cement factories, waste disposal facilities, majority of Polish power plants and many others.

Expert opinions on events connected with dust explosion (accidents, malfunctions)

Tests of the equipment according to 34/14/UE ATEX

Consultations related dust explosions, hazard associated with them and dust explosion protection systems

Selected projects:

- Research project for security and defense Technologie zabezpieczeń przeciwwybuchowych miejsc składowania materiałów sypkich, nr O ROB 0005 01/ID 5/1

- Prediction and Mitigation of Methane Explosions Effects for Improved Protection of Mine Infrastructure and Critical Equipment, RFCS Grant No. RFCR-CT-2014-00005, acronym EXPRO

Significant research:

- Research on explosions of hydrocarbons and vapours of flammable liquids in large scale

- Explosion pressure impact on the construction of grain silo

The Laboratory has many years of experience in testing elements of the natural environment, state of the environment, industrial products and wastes, etc. It is the first laboratory of waste testing in Poland which has been accredited by the Polish Centre for Accreditation.

The Laboratory conducts work within the framework of own, targeted and ordered research projects regarding new development and adaptation of existing analytical methods for analysing environmental samples and for analysing samples related to the industry.

The scope of activity of the Laboratory of Solid Waste Analyses includes various types of research objects, such as environmental samples (lands/soils), industrial solid wastes, solid fuels, building materials, filter beds and materials for contact with drinking water).

It should be added that expertise, opinions, assessments for industry, mining and environmental services are carried out in cooperation with the Division of Ecological Researches and the other laboratories of the Department of Environmental Monitoring GIG, in the field of, among others, soil and land pollution, environmental impact, or the use of wastes, e.g. on the surface of the earth and in the underground mining excavations.

The competent and experienced staff, application of the principles of professional laboratory practice and modern test and measurement facilities enable a wide range of tests, such as physicochemical analysis, technical analysis, determination of basic composition and trace elements as well as rare earth metals.

Samples delivered to the Laboratory should be protected against the possibility of moisture or secondary contamination (a sealed foil bag, jar, plastic container, etc.) and provided with a label containing basic identification data. The parcel should also contain the order (letter) for testing.

As the amount of sample delivered to the Laboratory and the time of analysis is due to the set / predicted scope of tests, the Customer should agree in advance the sample size with the Head of Unit.

|  |  |

The Laboratory of Water And Wastewater Analyses conducts research activities related to the development of new research procedures used in the analysis of natural and leachate waters with a high content of solutes.

As part of service work, the Laboratory performs annually over 3,000 physical and chemical analyses of water and wastewater in various tested materials, meeting the requirements of customers from the mining, energy, food, pharmaceutical, environmental protection, and other industries.

The subject of tests in the laboratory are drinking water, curative and thermal waters, surface waters, underground and industrial waters, leachate waters and wastewater (industrial, social and municipal facilities).

More than 100 physicochemical parameters are determined in the samples tested, using a variety of measurement techniques, including very modern ones, e.g. ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry), ICP-MS (Inductively Coupled Plasma - Mass Spectrometry), high temperature distribution techniques, IC (Ion Chromatography), flow techniques - injection FIA (Flow Injection Analysis) and continuous with stream segmentation SFA (Segmented Flow Analysis) with spectrophotometric detection.

The Laboratory of Water And Wastewater Analyses also carries out an assessment of the corrosive aggressiveness of water against concrete and steel on the basis of the analysis and tests carried out of the water for mixing concrete. The Laboratory conducts migration testing, determining the impact of materials on drinking water, jointly with the Laboratory of Solid Waste Analyses. The Laboratory performs also tests of food, road and bath salts and, to a limited extent (primarily metal content), tests of various foodstuffs.

Samples for testing taken by the Customer may be sent by courier to the address of the Laboratory or delivered in person to the same address.

|  |

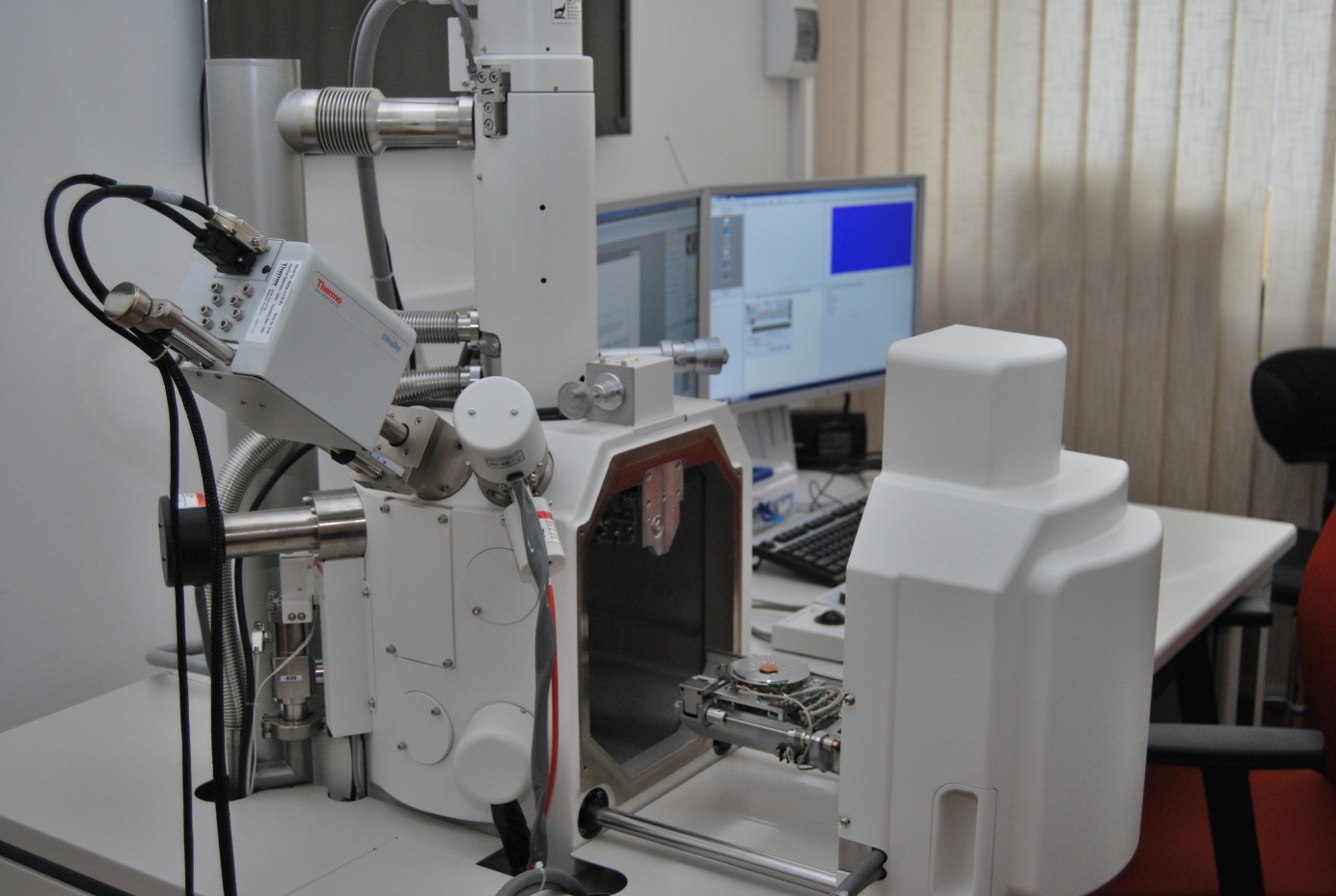

The Laboratory conducts research and service activities in the broadly understood mineral engineering. It covers issues related to the identification of the chemical and mineral composition as well as testing the technological characteristics of minerals and wastes.

The Laboratory is equipped with a modern digital scanning electron microscope Hitachi model

SU-3500N with an EDS attachment and a sputter, as well as an analyser of size, shape, and number of particles Morphologi G3S-ID, made by Malvern, with a Raman spectroscopy attachment for analysis to identify the chemical composition.

We carry out technological works aimed at defining and optimizing technical and technological conditions for valorisation and obtaining commercial products from minerals and wastes.

|  |  |

The technical equipment in the Laboratory and the staff experience allow testing and optimization of various industrial unit processes on a laboratory scale. We have the technical capabilities to carry out verification tests of suspension dewatering processes in a sedimentation-filtration centrifuge and a chamber-membrane press with blowing, on a full industrial scale.

We develop and consult concepts of technologies for the enrichment of mineral raw materials, instructions for running landfills, expertise in achieving the assumed ecological effects of investments, as well as tools and instruments supporting waste management.

We also deal with active social and labour market policy, strategic directions of development of communes and counties of the Silesian Voivodeship, demographic conditions of social policy, etc.

Equipment:

- Testing chamber according to UL-94

- Stand for flame tests

- Stand for the friction test

- Cone calorimeter + flue gas FTIR analyzer

- TGA thermogravimeter

- DSC differential scanning calorimeter

- Oxygen index stand

- Test stand according to PN-EN ISO 11925-2

- Test stand according to PN-EN ISO 1182

- Model adit PN-93/C-05013 point 2.4

- Test stand for the determination of thermal decomposition products

- Hot surface test stand PN-C-05019

- Test stand for the determination of Cleveland flash point

- Propane grate PN-EN 12881-1. Method C

- Pest stand (glowing / hot wire) according to PN-EN 606952

- Spectrophotometer Pharo 300

Additionally

- Foil press

- Granulator

- pH / conductivity meter

Research and development activities in the field of:

Utilization of solid fuels, including alternative fuels, and other materials (catalysts, sorbents) in energy and chemical synthesis applications:

- thermochemical conversion of solid fuels (coal, refuse derived fuels, biomass, industrial waste) for energy purposes and chemical synthesis, including combustion, pyrolysis and gasification processes

- development of economically efficient and environmentally friendly methods of utilization of solid fuels and waste materials in heat and electricity generation and chemical synthesis (synthesis gas, hydrogen)

- kinetic studies of combustion, pyrolysis, gasification and co-combustion, co-pyrolysis and co-gasification processes under atmospheric or pressurized conditions

- determination of fuel reactivity in thermochemical conversion processes

- determination of the composition of the product gas from thermochemical conversion processes

- studies on carbon dioxide capture and utilization

- application of catalysts in thermochemical conversion of solid fuels

- studies on chemical looping in thermochemical conversion of solid fuels

Characterization of materials: porous structure, physisorption and chemisorption, thermogravimetric analyses and spectrometric analyses:

- determination of the specific surface area, total pore volume, pore size distribution and sorption capacity of solids using a gas sorption analyzer

- temperature programmed reduction, oxidation and desorption analyses

- differential scanning calorimetry analyses

- thermogravimetric analyses under atmospheric and pressurized conditions

- spectrometric tests - high resolution spectra measurements in the full spectral range of infrared: near (NIR), middle (Mid-IR) and far (Far-IR) for samples in solid, liquid and gas form

Modeling of multidimensional data sets using advanced chemometric methods and taking into account their specific multimodal structure

Range of activities:

- Developing draft assumptions and plans for supplying municipalities / cities with heat, electricity and gas fuels

- Energy audits of an enterprise and industrial processes in accordance with the Energy Efficiency Act of 20 May 2016

- Audits of energy and renovation of residential and public buildings

- Development of Low Carbon Economy Plans, Environmental Impact Assessment (EIA) and Environmental Protection Programs

- Thermal tests for industrial installations and power boilers

- Technical, economic and research analyzes regarding the use of renewable energy sources

- Documentation, analysis and calculations regarding CO2 monitoring

- Conducting expertise for investments related to the reduction of energy consumption and emissions in order to obtain financial support from appropriate funds

Range of activities:

- Control measures for the emission into the air of dust and gas pollutants, including VOCs

- Measurement and investigation of the immission of dust and gas pollution in the air

- Calculations of diffusion of dust and gas pollutants in the air from technological emitters

- Preparation of applications for the introduction of dust and gases into the air in order to obtain decisions and assess the environmental impact of equipment and installations, especially in terms of impact on atmospheric air

- Measurement and testing of asbestos fiber concentrations in the air, including in the vicinity of buildings and objects from which asbestos is removed, and in confined spaces, based on results from an optical microscope and a scanning electron microscope

- Research on technology of production, modernization and construction of domestic boilers

- Research on harmful factors in the work environment

Range of activities:

- Conducting research and development on a large laboratory scale in the field of technical, technological and environmental issues of the underground coal gasification process

- Pressurized gasification of solid fuels

- The process of direct liquefaction of coal aimed at the production of liquid fuels and chemical raw materials

- Production of liquid fuels and chemical raw materials from biomass and waste materials by hydrothermal method

- Processes of hydrogenation and refining of carbonaceous substances

- Process gas separation using membranes and PSA

The Laboratory of Organic Compounds Analyses is involved in broadly understood environmental tests. We conduct research and service activities for environmental engineering, waste management, mining, construction, energy, chemical industry, food industry, and agriculture. We also do

non-commercial research that requires a scientific approach to the problem. The Laboratory cooperates with the Lab of Ecological Analyses and other laboratories of the Department of Environmental Monitoring.

The scope of activity of the Laboratory of Analysis of Organic Compounds includes testing of samples with various matrices: water, sewage, soil and land, waste, building materials, liquid mixtures, plants, and food products as well as water extracts/extracts.

We are a qualified group of chemists with many years of experience, and professionalism is our undeniable advantage. Over the years, we have created a constantly improving research team, open to new innovative analytical solutions. We guarantee reliable results for the most demanding customers.

Requirements for the execution of tests, in particular, the method of sampling, preservation, and transport to the Laboratory are strictly defined and require clarification by the Laboratory (email or telephone contact).