About the Experimental Mine "Barbara"

One of the most important research facilities the Central Mining Institute is the testing range of the Experimental Mine "Barbara", where tests on a large scale may be carried out.

The Experimental Mine "Barbara" was founded in 1925 by Związek Górniczo-Hutniczy [Mining-Metallurgical Federation]. The Experimental Station and the Central Office of Mining Rescue were transferred to it from Pniowiec. The new post was called the Experimental Mine "Barbara", the Central Office of Mining Rescue and the Magnetic Observatory in Mikołów. After 1933 it was financed from the funds of the Experimental Mine "Barbara" Association. Since the end of World War 2, the mine has worked as one of the main components of the project of the Central Mining Institute. Its main tasks are to improve the security and the speed of removing dust and gas hazards, which often occur in mines at great depths.

The Experimental Mine "Barbara" in Mikołów is the only research and scientific post in Poland and in Europe, with an experimental range for testing devices, equipment, materials and procedures in real underground conditions. The Experimental Mine "Barbara" has worked from 1925 protecting the safety in mining, as well as in other industries. It has also performed certification tests as the Notified Body the Central Mining Institute for the following directives: 2013/29/EU, 2014/28/EU and 2014/34/EU.

Dyrektor KD "Barbara"

e-mail: zlubosik@gig.eu

telefon: 32 259 24 70

Z-ca Dyrektora KD "Barbara"

e-mail: rhildebrandt@gig.eu

telefon: 32 3246 653

In the 91 years of its existence, both the direction of research as well as the role of the Experimental Mine "Barbara" in the system of the work safety in mining and in other industries have shaped.

Before World War 2, the subject of the activities were:

- explosive materials safe to methane and coal dust - formulas and test methods,

- safety of electric shooting (using electric detonators),

- first tests to reduce the range of the explosion of coal dust with explosion-proof barriers,

- first tests of electrical explosion devices.

Currently the Experimental Mine "Barbara" has the following structure:

- Mining Department, Department of Underground Research and Surface Maintenance (KD-1)

- Department of Dust Hazard Control (KD-2)

The Experimental Mine "Barbara" has closely cooperated since the beginning of its existence with its foreign counterparts and carries out research projects, conducted within the framework of international cooperation. These works

have always been highly rated. When in the thirties of the last century the organization of international conferences of Mining Safety Institutes began the Experimental Mine "Barbara" has participated in them since the beginning. Several times

these conferences were organized by the Central Mining Institute in Poland as well.

Within the framework of the European Union, the Experimental Mine "Barbara" took part in the research works among others in the following projects:

- HUGE (Hydrogen oriented underground coal gasification for Europe, 2007 2010),

- HUGE2 Hydrogen oriented underground coal gasification for Europe - Environmental and Safety Aspects.

- GASDRAIN (Development of Improved Methane Drainage Technologies by Stimulating Coal Seams for Major Risk Prevention and Increased Coal Output).

The Experimental Mine "Barbara" has been realising, as the Notified Body in the European Union with the number 1453 which is the Central Mining Institute the processes of conformity assessment of products under the following directives:

- 2014/28/EU related to the making available on the market and supervision of explosives for civil uses,

- 2013/29/EU on pyrotechnic articles,

- 2014/34/EU (ATEX) equipment and protective systems intended for use in potentially explosive atmosphere.

New research capabilities of the Central Mining Institute based on the training ground of the Experimental Mine "Barbara"

The progress of science, the creation of new technologies and technical solutions in the micro and macro scale forces the development of modern research laboratories, without of which the progress would be impossible. This applies especially to technologies and products implemented into production where without the proper scientific-research backend, progress would be impossible. Unfortunately, the costs of constructing and equipping such laboratories are very high. Central Mining Institute recognises these problems and equips its laboratories with modern equipment and laboratory apparatus, constructs new research centres (including Clean Coal Technologies Centre) as well as undergoes certification (IECEx) in order to expand the range of services provided for the benefit of industry and science. One of the most important research facilities of the Central Mining Institute is the training ground of Experimental Mine "Barbara", where large-scale research may be carried out.

Below, we present test stands, giving examples of conducted research in order to explain the scope of research.

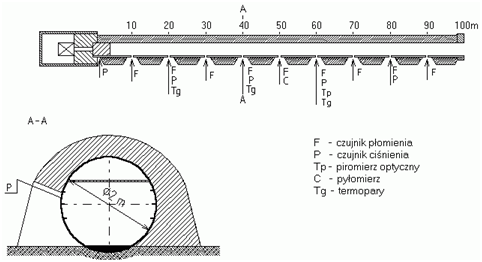

Since its creation, that is, since the 1960s, the experimental tunnel (fig. 1) has been used to perform over 3500 test explosions of dust and hybrid mixtures. Of course, for the most part various types of coal dusts were tested. However, also many other industry dusts have been used for research. For example, a comprehensive survey of cereal dust explosion which was carried out for the United States Department of Agriculture.

Fig. 1. The scheme of the experimental tunnel of 100 m length along with measurement set.

The tunnel is constituted by a 100 m steel pipe, 2 m in diameter, closed at one end and open at the other. Every 10 m, starting from the closed end, there is access to the tunnel wall, enabling installation of various types of measuring equipment. Most often, the explosion is started by initial explosion at the closed end of the tunnel. In such conditions, the explosion of a mixture of air and dust develops in the direction of the open end of the tunnel. The ease of installing measuring equipment and the opportunity to observe the explosion at its end phase are the main reasons for which the experimental tunnel is used as a research tool. On the other hand however, due to the tunnel's limited strength, only weak explosions can be performed, in which overpressure does not exceed the value of 1 bar. Lately, the tunnel has been used to study the propagation of explosions of hybrid mixtures containing coal dust and methane. In these tests, to the dust-air mixture was added a slight amount of methane, with the concentration permitted in Polish mines, and the influence of methane additives on the propagation of hybrid mixture explosion was determined.

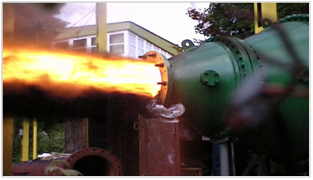

Another type of experience performed for many years with the use of tunnels are researches of fire-extinguishing properties of dust used to spray mine workings. In accordance with Polish regulations, dusts, with the exception of limestone dusts, which are intended to be used for that purpose, must first be tested in real scale. The tunnel has also educational purposes. Coal dust explosion in the tunnel is demonstrated to all participants of vocational training organized by the Central Mining Institute (fig. 1.)

Photograph 1. Coal dust explosion in the experimental tunnel of 100 m

Two chambers of a volume of 1 m 3each, fulfilling all the requirements of standards PN-EN 14034, serve mainly for the determination of the parameters of the dust-air mixture explosions. There are also research and usable works conducted on the explosive parameters of dust mixtures, gases or flammable liquid pairs with air and/or inert gases. It is also possible to test, thanks to them, the so-called hybrid mixtures

Photograph 4. Test chamber of 1 m3

The latest test stand enabling tests on industrial scale in the Experimental Mine "Barbara" of the Central Mining Institute is the 5 m3 test chamber. This chamber has been made for the purpose of carrying out research in the Airpipe project of the V Framework Programme of the European Union. However, the Chamber design enables carrying out a wide range of explosion tests of dust and gases for both practical and scientific purposes.

The entire test stand consists of a chamber with cylindrical (fig. 2) of characteristic dimension relation of L/D < 2 as well as of a piping section. The chamber is equipped with a dispersion system, which enables to generate explosions of repeatable parameters. It is also possible to produce homogeneous gas-air mixtures. To the outlet of the chamber can be attached three sections of pipes, each with a length of about 5 m and a diameter of 500 mm, forming a wire, by which the explosion from the chamber is conducted. Pipes are mounted on mobile supports, enabling easy changes in test configuration.

Photograph 2. Test chamber of 5 m3

The first studies conducted on this post were intended to obtain information about the characteristics of different materials used in the construction of new explosion insulation systems. The Photograph 3 shows an example of a coal dust explosion in the chamber of 5 m3. During this test, the outlet hole of the chamber was closed with a membrane made of kevlar. The next already scheduled tests will rely on the study of the propagation of an explosion in the pipe wire that is joined to the outlet hole of the chamber. It is also planned to test various industrial dust explosion properties, as pigment dust, coal dust or corn starch.

The chamber is also used to test the effectiveness of different protective systems functioning against the effects of explosion. This type of testing is necessary in the process of certification tests. It is required that the efficiency of systems of explosion attenuation and isolation, as well as proper functioning of the systems of decompression and detection, should be confirmed in a large scale tests.

Photograph 3. Coal dust explosion in the chamber of 5 m3

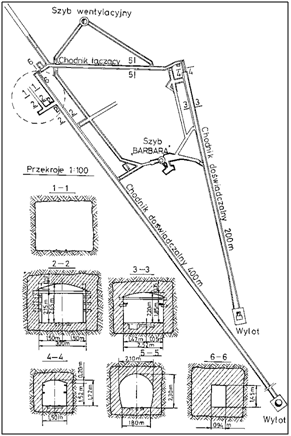

The network of underground experimental headings (fig. 2) is a unique test stand of the Experimental Mine "Barbara" for testing in a large scale. In these headings, large explosions of dusts and gases are carried out, as well as the courses of explosions on the complex geometry of excavations are examined. In the experimental headings of EM "Barbara" very strong dust explosions have already been generated, including the detonation of a dust-air mixture (fig. 4). These experiences are probably the first and so far the only examples of detonation of the dust-air mixture in full scale.

Fig. 2. Plan of the underground experimental headings of EM "Barbara"

Photograph 4.Coal dust explosion in the experimental heading with a length of 400 m

The system of experimental headings of EM "Barbara" includes several mining excavations, of which the most important are the two headings of lengths of 400 and 200 m. Both headings are equipped with measuring panels arranged along the walls of the excavation. Panels enable to install different types of measurement devices, depending on the needs and purpose of the test. Due to the geometry of the headings, there is the possibility of carrying out studies in joined excavations with different points of explosion initialisation. In the experimental heading of 200 m, the test stand with a section of 11 m2 for testing the strength of explosion barriers (fig. 5) is located.

Photograph 5. Explosion barrier closed

Photograph 5. Explosion barrier open

Due to their specific properties, underground headings were used in tests of very different types. Recently, the tests of effectiveness of new dust barriers constructions were carried out. Different barriers have also been tested. As the automatic explosion barriers gain popularity, numerous tests concerning their effectiveness have been carried out in the experimental headings. One of the examples of a completely different type of research is the test in the headings on the effectiveness of ventilation system valve designed for use in subway. On the basis of the underground testing ground, the new project of the Research Fund for Coal and Steel of the European Commission concerning the underground gasification of coal has been initiated.Due to their specific properties, underground headings were used in tests of very different types. Recently, the tests of effectiveness of new dust barriers constructions were carried out. Different barriers have also been tested. As the automatic explosion barriers gain popularity, numerous tests concerning their effectiveness have been carried out in the experimental headings. One of the examples of a completely different type of research is the test in the headings on the effectiveness of ventilation system valve designed for use in subway. On the basis of the underground testing ground, the new project of the Research Fund for Coal and Steel of the European Commission concerning the underground gasification of coal has been initiated.

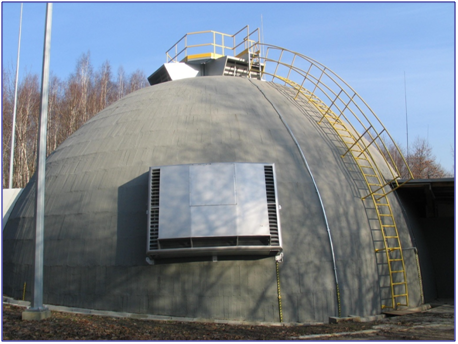

After Polish accession to the European Union (EU) on 1 May 2004, for blasting agents called explosive materials, in accordance with Directive 93/15/EEC of 5 April 1993, a new launching mode on the market in Member States of the EU has been introduced. For this reason, among others, preparations and investments lasting for many years not only in research equipment but also in the training of personnel of the Central Mining Institute, have resulted in granting the authorisation for the Institute by the Polish Government, inter alia with regard to conformity assessment of explosive materials in accordance with the mentioned directive, and then granting, by the European Commission, the status of Notified Body number 1453. The Central Mining Institute (CMI) faithfully implements the provisions of the Directive 93/15/EEC in assessing articles, i.e. explosive materials of Polish and foreign manufacturers. This is generally done in accordance with European standards harmonised with the directive, concerning tests of explosive materials. These studies take place at CMI's testing ground in Experimental Mine "Barbara". The biggest research capabilities while reducing the impact on the environment are created by the latest investments in the testing ground in the form of a sound absorbing bunker and experimental drift. most of the tests of explosive materials by detonation (e.g. speed and transfer of detonation and sensitivity on detonation initiation) are performed in the shooting bunker of unusual hemispherical construction. This reinforce concrete object has a sound absorbing ventilation intakes with special silencers limiting noise, due to the tougher current European standards in the aspect of noise emitted into the environment (fig. 6, 7).

Photograph 6. Shooting bunker in CMI's Experimental Mine "Barbara"- view from the outside

Photograph 7. Shooting bunker in CMI's Experimental Mine "Barbara"- view from the inside

In order to determine the degree of safety of explosive materials to mixtures of air with coal dust or methane, the test stand in the form of experimental drift is necessary. In the modern new experimental drift in the shape of steel tube with diameter of 2000 mm and a length of 44 m (fig. 8) safety tests for explosive materials are carried out, including detonating fuses and electric detonators to methane and coal dust. The drift is open from one end (the output of the drift), and closed from the other with a massive concrete block (face of the drift). Inside of it there is one of the various types of mortars, simulating the distinct ways of casting products of detonation from the blasting holes. Studies are focused primarily on the test of methane or coal dust inflammation by detonating explosive materials, fuses and detonators.

Photograph 8. Experimental drift of 44 m – general view

In order to test explosive materials, measuring instruments of high standard are used, among others the apparatus to measure the detonation speed of explosive materials with built-in fibre-optic sensors EXPLOMET FO 2000 of the Swiss company KONTINITRO (fig. 9).

Photograph 9. EXPLOMET FO 2000 fibre-optic sensors

In recent years, the new methodology applied to the study of shooting gases after detonation of explosive materials has been developed on the basis of European requirements. For this purpose there has been built the laboratory test stand (fig. 10) to detonate explosive materials in mining mortar placed inside the shooting chamber, combined with the measuring apparatus in the form of two analysers. The analysers enable, in accordance with the requirements of the standard harmonised in this aspect, continuous measurement of concentration of gaseous components in the products of detonation. i.e. carbon oxides CO, CO2 and nitrogen oxides NO, NO2.

Photograph 10. Test stand to study shooting gases after detonation of explosive materials

For testing the electrical parameters and detonation times for electric detonators, non-electric and electronic, in accordance with European harmonised standards, there is a modern fully computerised test stand shown in fig. 11.

Photograph 11. Automatic stand to test fuses

One of the recently completed new investments is the construction, in accordance with the European standard in this regard, of the stand for the research of thermal stability of explosive materials (fig. 12). The stand enables secure conditioning of samples of the explosive materials in the pre-set temperature and time, in a thermal chamber with remote control and monitoring of the course of study.

Photograph 12. Stand for research of thermal stability of explosive materials

In the Experimental Mine "Barbara" the certification tests for equipment and protective systems intended for use in potentially explosive areas are carried out. The tests are carried out in the Laboratory with the accreditation of the Polish Centre for Accreditation (since 1995) and confirmed research competence in the international IECEx scheme.

The Laboratory carries out tests from accredited as well as non-accredited area with the use of held, metrologically supervised measurement and research equipment. Basic research is carried out with the use of a wide range of explosive mixtures of gases as well as vapours of flammable liquids. They are created in the Laboratory using computer-controlled, mass flow meters. Tests are carried out, among others, with the use of the test chambers with volumes of: 0.25 m3, 0.75 m3, 2 m 3and 16 m3. Test stands enable carrying out research of all security types of electrical and non-electrical devices from group I (for use in mining companies) and of groups IIA, IIB and IIC (for use in other industries). Devices designed to operate in atmospheres of potential dust explosion are also tested (group IIIA, IIIB and IIIC). The largest chamber enables testing the flameproof enclosures of masses exceeding 6000 kg (fig. 13). Tests may be performed at atmospheric pressure, as well as in terms of hypertension.

Photograph 13. Test chamber with a volume of 16 m3

Photograph 14. Test chamber with a volume of 64 m 3with a mining diesel locomotive

Photograph 15. Transfer of the explosion from the inside of the flameproof enclosure of electric motor – a study on the testing ground of the Laboratory

The stand, in a large scale, used for similar purposes is the test chamber with a volume of 64 m3, intended to test locomotives (fig. 14). An example of works carried out on the testing ground is testing of the construction of flameproof engine enclosure (fig. 15).

Photograph 16. Chamber for low temperature tests

Test stands enable conducting explosive studies of devices at low temperatures (-55 ° c) Fig. 16.

The essential element of the assessment of the tendency of coal to undergo gas-geo-dynamical phenomena, including methane and rocks outbursts, is the study of methane sorption phenomenon in coal. The analysis is mainly conducted on the coals from decks of high methane saturation, coals from parts of decks with methane and rock outbursts hazards and places in deck, where there are methane content anomalies often resulting in discharging gas or increased methane emission to mining workings during extraction. The tests are also carried out on decks in situations where basic emergency indicators, i.e. methane content, bore dust flow-off, brevity and intensity of desorption measured with DMC-2, determine imprecisely the outburst risk status and when there are doubts regarding the inclusion of the deck or part thereof to decks susceptible to or threatened by methane and rock outburst.

Determining the tendency of coal decks to coal and rock outburst is based inter alia on the laboratory examination and analysis of methane sorption in coal to identify changes in its structure. Structural change of coal in many cases is the result of an action of the forces in the tectonically perturbed zone causing anomalies in the distribution of factors conditioning the outburst phenomenon, that is gas pressure, tension, geomechanical properties of a deck.

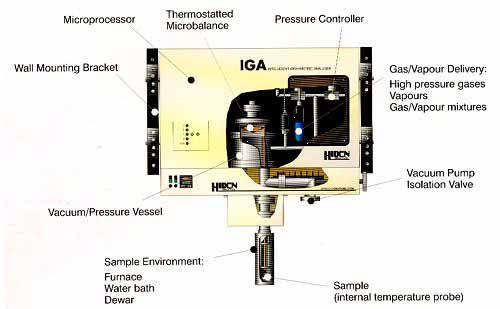

In the Department of Gas Hazard Control of EM "Barbara" to test gas sorption (mainly methane) is used the laboratory apparatus basing on the direct measurement of the amount of adsorbed gas. Research on methane adsorption is carried out based on the gravimetric method on Sartorius microscales and IGA-001 analyzer. The research methodology is similar to Ettinger's methodology

Photograph 1. Intelligent Gravimetric Analyser IGA-001

Photograph 1. Intelligent Gravimetric Analyser IGA-001

The test apparatus enables, under certain conditions of pressure and temperature, to set:

- the quantities of methane, carbon dioxide and other gases in coal porous structure (the so-called sorption capacity),

- sorption kinetics depending on the dynamics of gas pressure and temperature changes,

- the effective diffusion coefficient,

- sorption isotherms, which in conjunction with methane content values enable to specify the deposit pressure of gas in a deck.

Determined sorption parameters depend, to a large extent, on coal structure and on research conditions, that is gas pressure and its temperature. Measuring range of gas parameters, that is temperatures up to 200° C and pressure up to 2 MPa (IGA Analyzer-001) or up to 18 MPa (Sartorius microscales) enables to conduct research in conditions similar to the real ones.

Sorption system IGA-001 is equipped with a controlling and registering module cooperating with a computer. IGASwin software provides, inter alia, full control over the course of the experiment, a graphical visualization of results, analysis of sorption kinetics in real time. To the system is also introduced a programmable cycle sequence measuring mode, depending on the results of the analysis of sorption kinetics, carried out in real time. The software has the ability to save all recorded parameters and the results of the analysis on a drive. It is also possible to export data in the form of ASCII files.

Bibliography:

Ettinger I. L. 1952 : Index for susceptibility of coal to gas and coal outbursts, Ugol, 1952, No. 10, 1952 pp. 31-34 (in Russian)