- rock mass and surface deformation prediction caused by underground exploitation;

- evaluation of mining impact on various elements of land use;

- risk assessment of discontinuous deformation occurrence in mining areas;

- determination and verification of the mining area boundaries;

- boundaries determination of areas requiring transformation or reclamation, with particular consideration given to the risk of water flooding as a consequence of natural water flow restoration;

- categorisation of mining areas in terms of the predicted mining surface deformation;

- flooding risk assessment of mining and post-mining areas;

- assessment and categorisation of post-mining areas suitability for spatial planning, including building development in particular;

- optimisation of underground mining exploitation projects in terms of the surface and its land use protection;

- verification of mining plant operation plans in terms of the surface protection and the compatibility with local spatial planning;

- classification of industrial mineral resources with consideration given to the surface and its land use protection;

- determination and verification of safety pillar boundaries.

- structures and utility infrastructure networks protection against mining impact;

- structure technical condition evaluation and diagnosing the causes responsible for the damage to said structures;

- stock-taking and evaluation of static and dynamic resistance of structures exposed to mining impact;

- development and implementation of new resistance evaluation methods for structures and technical infrastructure networks exposed to the impact of deformations and mining tremors;

- predicted effect determination of designed mining impact on building land development;

- safety and reliability evaluation of structures in mining areas and the anticipated inconveniences related to their use;

- operating conditions evaluation of utility infrastructure networks exposed to static and dynamic mining impact;

- threats determination for the operational safety structures in mining areas;

- complex cause and effect evaluations of the deviation of structures from the vertical in mining areas;

- evaluation of damage to structures and the surface from the perspective of its relation to mining plant operations;

- determination of protection and reinforcement methods for existing structures exposed to the impact of mining-induced subsoil deformations and mining tremors;

- structures and utility infrastructure networks protection in post-mining areas;

- threats identification and definition for structures in post-mining areas;

- suggesting optimal preventive and protective measures for existing and planned structures in mining and post-mining areas;

- consultation and evaluation of the projects of structures planned for mining and post-mining areas;

- consultation and evaluation of the construction projects of utility infrastructure network sections employing trenchless methods;

- evaluation of the action projects regarding surface water regulation and flood protection, as well as mining and post-mining areas reclamation and revitalisation, with consideration given to the risk of water flooding as a consequence of natural water flow restoration;

- evaluation of documentations concerning the environmental protection in terms of predicted mining impact;

- evaluation of technical documentations concerning mining damage repairs;

- laboratory testing of materials and products employed for utility infrastructure network construction, particularly of pipes, fittings, manholes, tanks, compensators and other utility infrastructure network elements from the perspective of their usage in mining and post-mining areas;

- laboratory testing of geosynthetic materials intended for soil reinforcement, as well as the possibility evaluation of their usage in mining areas;

- monitoring of the area surface and structures subject to mining impact;

- mining area surface scanning;

- structures scanning;

- automatic continuous monitoring of the deviation of structures from the vertical;

- recording and evaluation of the technical condition of structures using drone technology.

Scope of mine ventilation

- Ventilation system design for mines, industrial sites and structures

- Analysing ventilation costs, and reviewing methods for their reduction

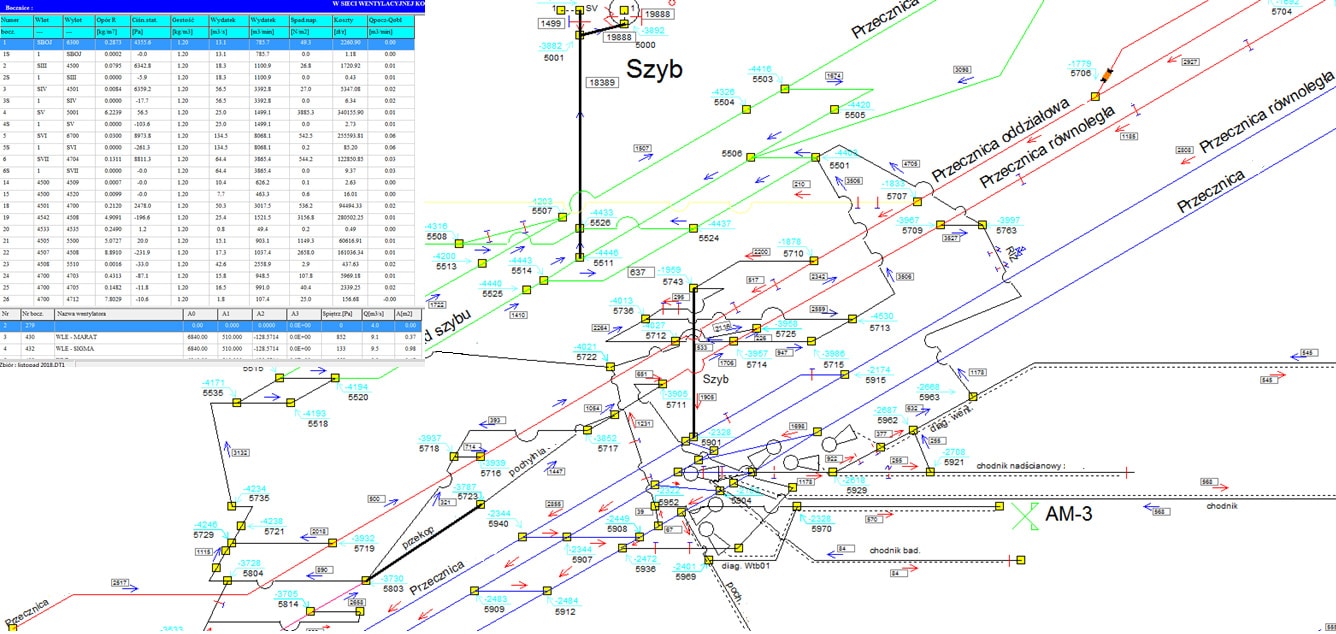

- Preparing mine ventilation system plans and air flow diagrams, and their analyses

- Expert opinions concerning methane, dust, fire and radiation hazard prevention by means of ventilation measures

- Preparing main fan characteristics according to standard PN-70G-04161, and analysing the stability and efficiency of their operation

- Inspecting gas migrations in mine workings using the SF6 tracer gas

- Inspecting site airtightness using the SF6 tracer gas

- Variant-based analysis for simplifying the ventilation system models of decommissioned mines under the conditions of co-occurring gas hazards

- Developing working isolation technologies in decommissioned gassy mines

- Taking pictures of potential mine ventilation systems

- Computer-based characteristics of mine ventilation systems using the Ventgraph program

- Ventilation tubing system design

- Designing auxiliary ventilation systems for gallery workings driven in gassy deposits

- Tests and assessments of gas hazards for successive stages of decommissioning for the workings, areas, levels and shafts of decommissioned mines

- Numerical calculations (3D) of forecast air propagation in underground workings, and calculations of dust and methane concentrations in the ventilation air

- Numerical calculations with analyses of the ventilation systems of planned extraction areas under the conditions of methane and spontaneous fire hazard occurrence

- Numerical calculations and design of extraction work for extraction areas beneath the development level

- Developing working isolation technologies in decommissioned mines

- Designing tunnel ventilation during tunnelling and extraction

- Energy performance tests of blower fans, pumps, compressors

- Numerical calculations and design of extraction work for extraction areas beneath the development level

- Numerical calculations with analyses of the ventilation systems of designed extraction areas under the conditions of methane and spontaneous fire hazard occurrence

- Ventilation tube drag testing

Scope of mine air conditioning

- Preparing virgin rock temperature isolines for planned extraction levels, coal seams and copper ore beds

- Assessing geothermal conditions based on virgin rock temperature isolines for active and planned extraction levels, coal seams and copper ore beds

- Forecasting climatic hazards in workings with auxiliary ventilation (tubing) systems

- Forecasting climatic hazards in workings with main air currents

- Testing and assessing climatic hazards for workstations

- Forecasting climatic hazard states for designed workings ventilated via ventilation tubing

- Forecasting climatic hazard states for designed workings ventilated via recirculation of air

- Designing ventilation and air conditioning for deep extraction levels and the entire mine

- Evaluating the preventive measures taken against climatic hazards

- Preparing conceptual designs of combined air conditioning systems

- Formulating expert opinions on mining plant operations for group XX (climatic hazards) regarding preventive measures ensuring the maintenance of appropriate effective temperature in workings driven in a rock mass exhibiting a virgin temperature higher than 40oC

- Thermal testing of electrical equipment

- Preparing effective preventive measures against climatic hazards for extraction areas

- Testing and implementing solutions for the improvement of mine cooling system efficiency

- Measuring and analysing the efficiency of mine cooling systems based on in situ measurements

- Expert opinions concerning lower air conditioning costs

- Defining the principles of employing miners in hot microclimates

Scope of gas hazard prevention

- Forecasting methane emissions to extraction, preparatory and development workings

- Opinions regarding the classification of coal seams or their parts and methane fields into the appropriate categories of methane hazards and gas and rock outburst hazards

- Classifying workings (rooms) with regard to the appropriate levels of methane explosion risks

- Complex assessment of methane hazards and spontaneous fire hazards in planned extraction areas

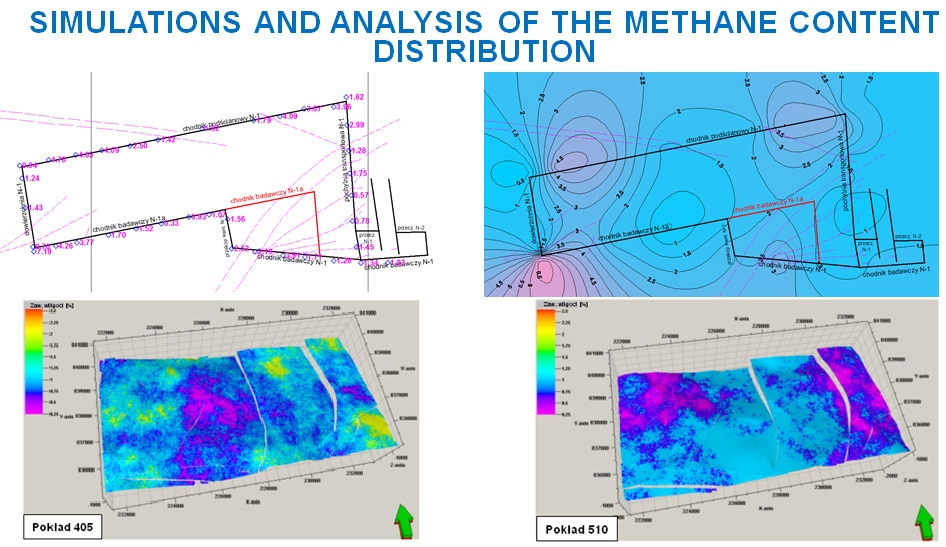

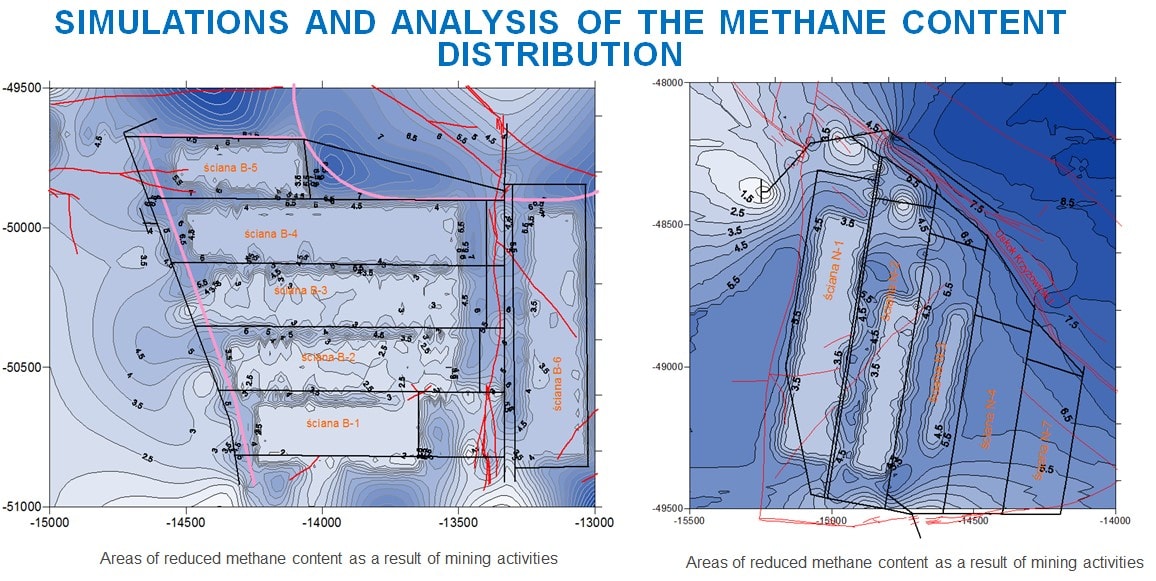

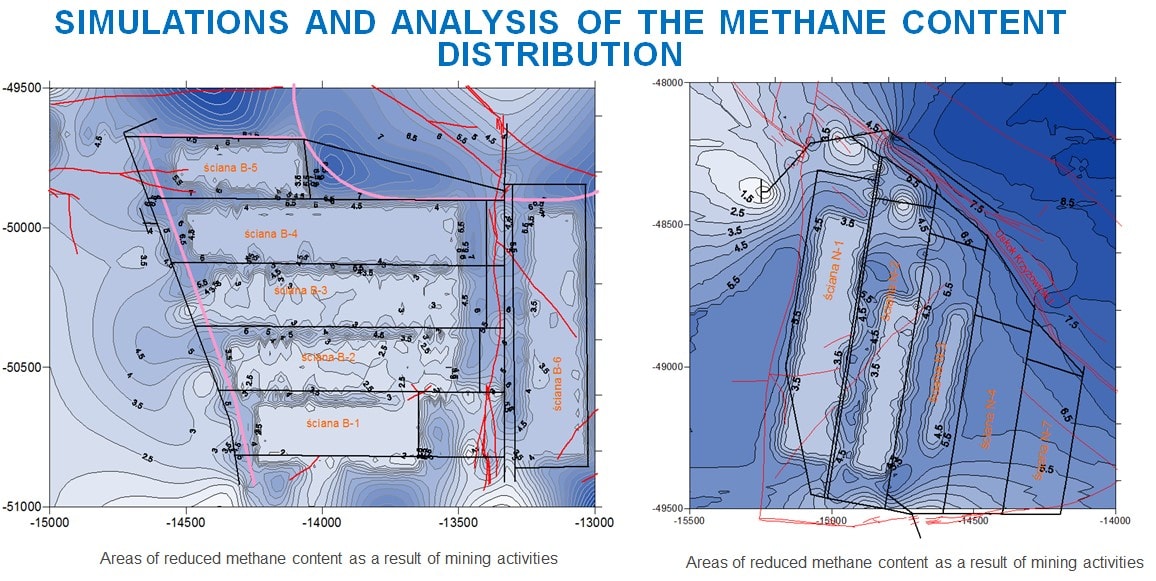

- Simulations and analyses of the methane content distribution in coal seams

- Assessment of the generation of methane hazards for mined longwalls, factoring in the ventilation and methane conditions and the scope of applied preventive measures

- Balancing the free methane accumulated in decommissioned mine workings in conventionally adopted time intervals, in relation to hydrogeology, tectonics and conditions related to adjacent mines

- Forecasting the likelihood of gas hazard occurrence on the surface within the area of a decommissioned gassy mine

- Testing the kinetics and flow intensity of mine gases into the near-surface zone within the area of a decommissioned mine

- Developing methods for the active prevention of gas hazards in near-surface zones within the post-mining areas of decommissioned mines

- Developing deposit stimulation technologies for increased deposit permeability and for the pre-extraction methane drainage of coal seams (hydroslotting), and CBM support technologies

- Assessment of the generation of methane hazards for mined longwalls, factoring in the ventilation and methane conditions and the scope of applied preventive measures, including methane drainage

- Developing technologies for methane recovery from coal deposits and use

- Expert opinions regarding the methane drainage methods applied in extraction areas

- Designing methane drainage systems in mines and the trajectories of directional boreholes

- Analysing the methane and rock outburst hazards in coal seams or their parts with regard to the classification and delimitation of classification into the appropriate categories of outburst hazards, and with regard to preventing said hazards

- Balancing the free methane accumulated in decommissioned mine workings in conventionally adopted time intervals, in relation to hydrogeology, tectonics and conditions related to adjacent mines

- Forecasting the likelihood of gas hazard occurrence on the surface within the area of a decommissioned gassy mine

- Testing the kinetics and flow intensity of mine gases into the near-surface zone within the area of a decommissioned mine

- Developing methods for the active prevention of gas hazards in near-surface zones within the post-mining areas of decommissioned mines

- Forecasting methane capture from extraction boreholes (CBM) and surface boreholes to virgin coal seams, i.e. outside extraction range, (CBM) based on the results of numerical modelling using the Petrel, Eclipse and AnSys CFX software

Scope of gas and rock outburst hazard prevention

- Forecasting the state of outburst hazard for newly-developed and poorly explored parts of a deposit

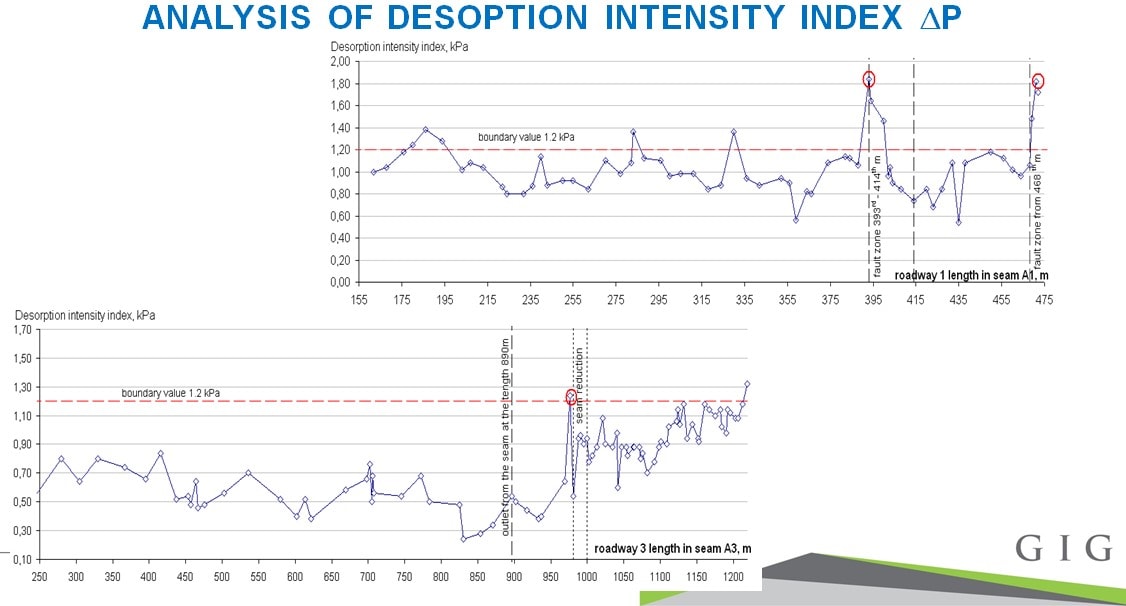

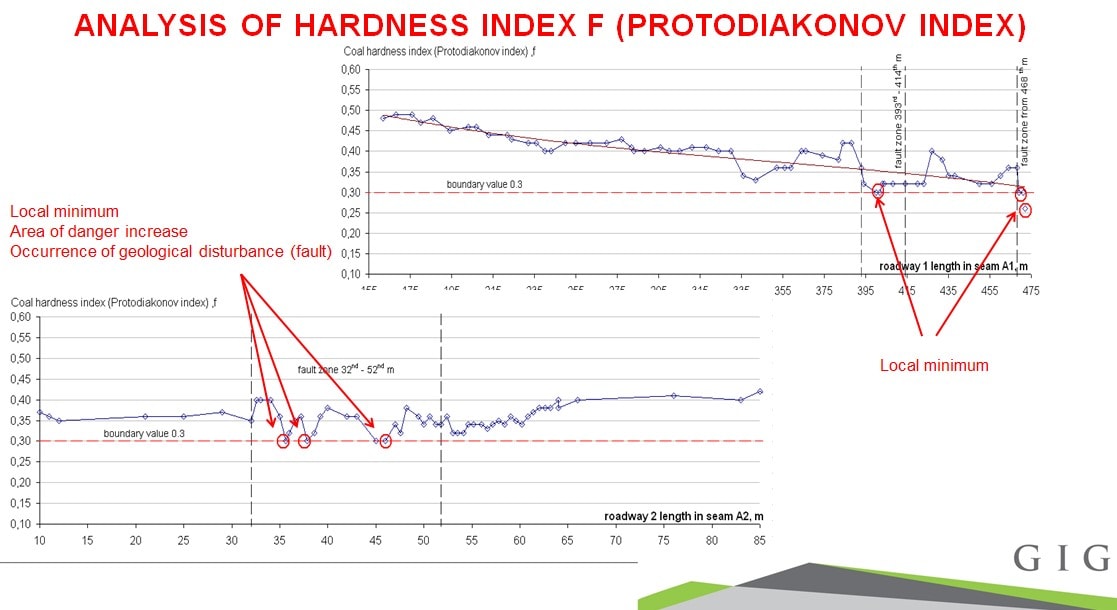

- Conducting in situ measurements of the basic indicators of outburst hazard states used for coal mines, i.e. methane desorption intensity, methane content, volume of borings and coal cohesion, in order to provide an assessment of the current state of the outburst hazard or to prepare a current forecast

- Analysing the methane and rock outburst hazards in coal seams or their parts with regard to the classification and delimitation of classification into the appropriate categories of outburst hazards, and with regard to preventing said hazards

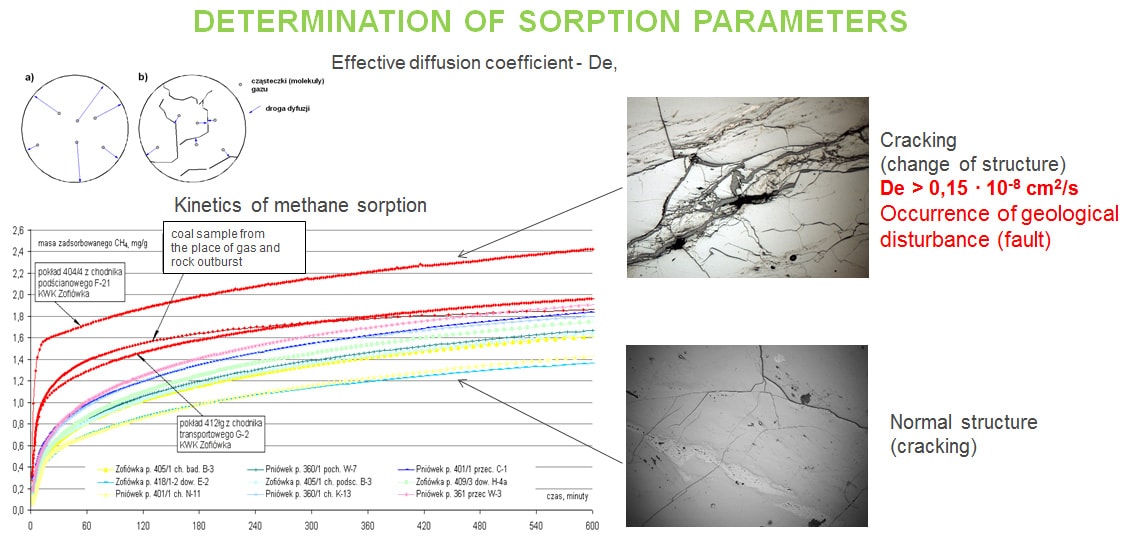

- Conducting complex tests of coal seams (rocks) in order to determine their predispositions for outbursts, encompassing extended measurements involving sorptive properties, i.e. sorption kinetics and effective diffusivity

- Formulating opinions regarding the technical design of mining activities conducted under the conditions of outburst hazards, planning deposit (coal seam) development, and designing ventilation systems and protections under the conditions of the aforementioned hazards

- Delimiting the classification of a coal seam into the appropriate outburst hazard category, and formulating opinions concerning the possibility of excluding a part of the coal seam from the boundaries of its current classification into an appropriate outburst hazard category

- Assessing the effectiveness of preventive measures taken against outbursts in mines and preparing the (principles of) preventive measures for specific mining activities performed in zones exhibiting a particularly high risk of hazard occurrence

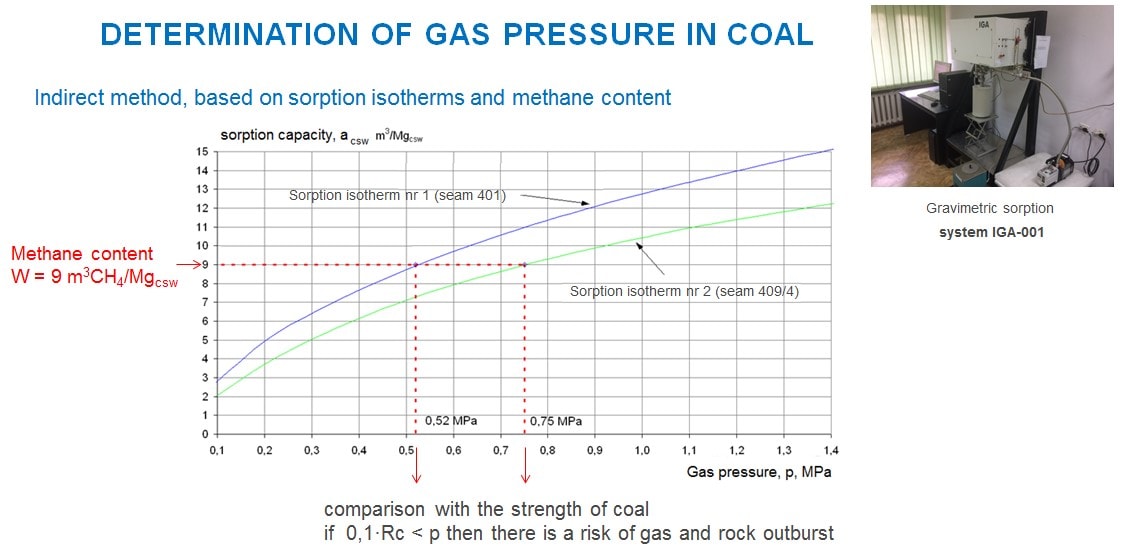

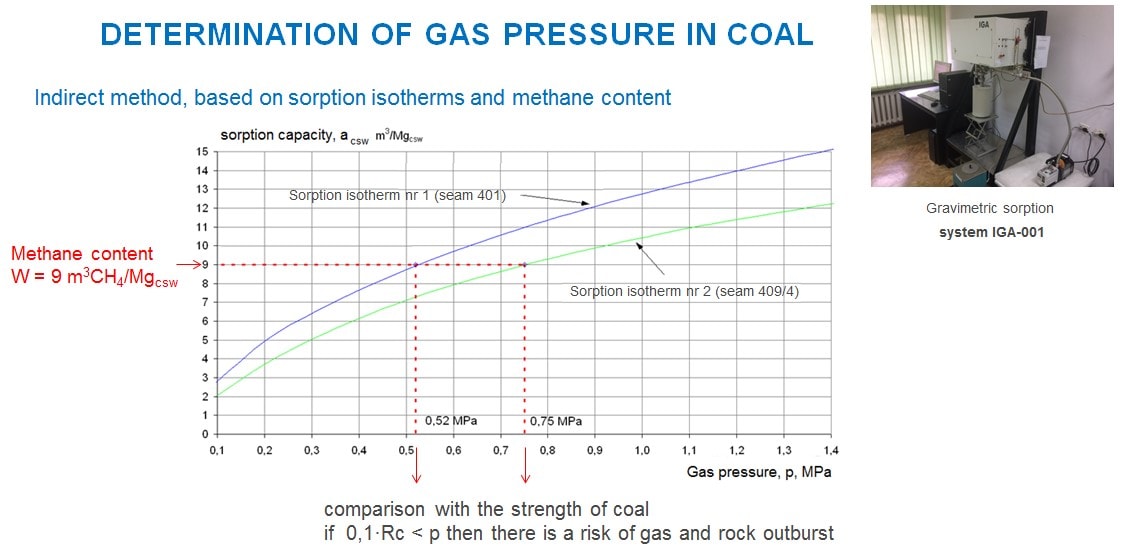

- Analysing sorption isotherms in order to determine the coal seam pressures and predispositions for outburst (gasogeodynamic phenomenon occurrence)

- Delimiting extraction degassing zones in an analysed coal seam and simulating the distribution of remaining methane content with regard to opinions and forecasts concerning outburst hazards

- Simulating the distribution of methane content and coal seam gas pressures in a deposit

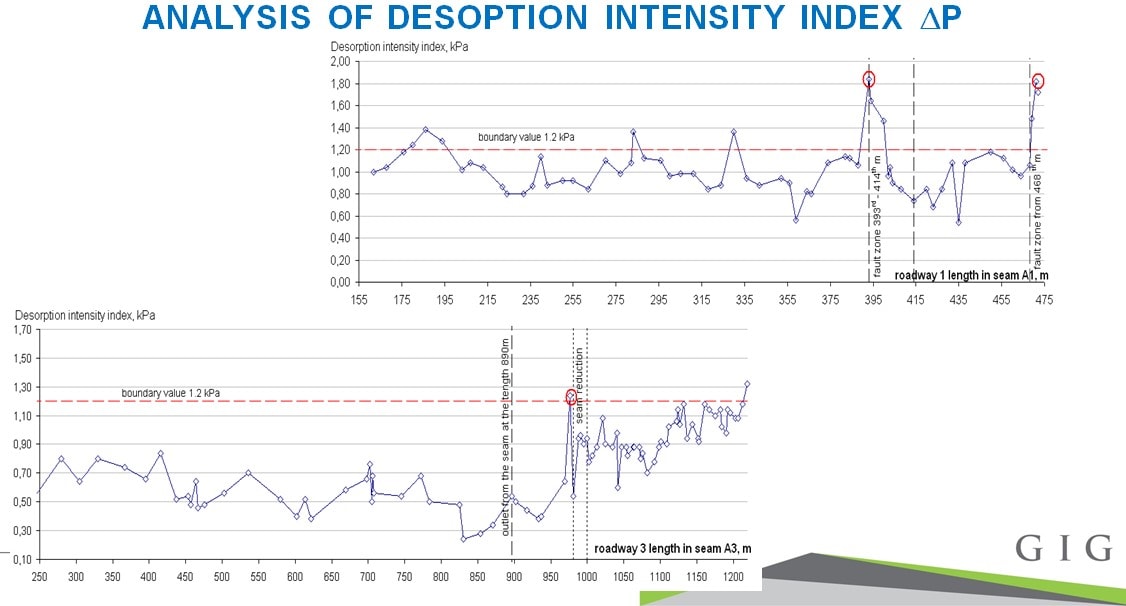

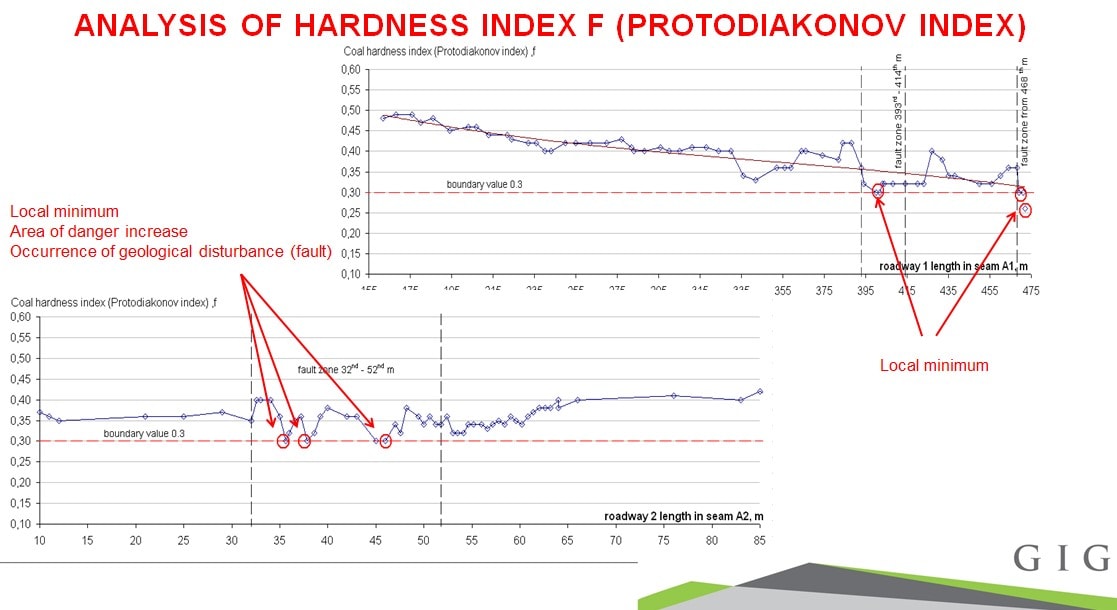

- Analysing the changes in the basic indicators of the state of outburst hazard, i.e. methane desorption intensity, coal cohesion, and assessing the influence of geological disturbances (faults) on the geotechnical properties of coal seams

- Thermal testing of air-conditioning equipment

- Mine air-conditioning methods

- Mapping of rock primary temperature isolines for designed extraction levels and deposits

- Evaluation of geothermal conditions based on maps of rock primary temperature isolines for active and designed extraction levels and coal seams

- Prediction of climate hazard in the workings ventilated by both the main and auxiliary ventilation systems

- Development of model climatic solutions for underground workings with auxiliary ventilation

- Development of effective climate hazard prevention methods for mining panels

- Tests and implementation of solutions to improve the operation efficiency of mining cooling equipment

- Design of ventilation and air-conditioning systems for deep extraction levels and entire mines

- Expertise on reducing air-conditioning costs

- Rules of employing miners in hot microclimate

The scope of research and expertise:

- determination and assessment of hydrogeological conditions of mining exploitation or mine closure, including preparation of hydrogeological studies and documentation for hard coal mines;

- identifying and preventing water hazards, establishing safety pillars and conditions for mining exploitation, as well as planning drainage of the rock mass and assessment of mine drainage systems;

- assessment of water hazard in connection with the operation and abandonment of mining shafts;

- risk assessment related to the possibility of a water hazard in underground mines;

- concepts, opinions, expert opinions, model and project solutions, and so-called Master Plans for the elimination and simplification of mine drainage systems along with the assessment of the hydrogeological consequences of the proposed changes;

- simulation tests, assessment and forecasting of the proces of mine workings flooding in active and abandoned mines;

- studying and assessment of impacts of changes of water conditions within rock mass and on surface associated with mining activities and mines closure;

- determining the possible impact of changes in hydrogeological

- conditions, water conditions and water hazards on

- the occurrence of changes in geomechanical conditions,

- balancing of free methane in excavations of active and

- abandoned mines, as well as on the state of water resources and their energy;

- strategy and concepts of limiting the salinity of mine water and activities to increase the possibilities of their economic use;

- hydrogeological monitoring studies to determine the conditions and impact of mining excavations and the impact of mining and industrial activities on the environment, including the assessment of the common threat (rock mass tremors, water and gas outflows, groundwater pollution, cavities hazards, etc.);

- examination of hydrogeological properties of rocks and rock debris (porosity, permeability, gravity drainage) for clarifying the conditions of storage and flow of water and gases in the processes of mining exploitation and mine and shaft abandonment, as well as in the assessment of hydrogeological conditions, groundwater resources and their energy and water hazards;

- construction of numerical hydrogeological models using Processing MODFLOW and FeFLOW software and multidimensional simulations;

- modelling of hydrogeological processes and phenomena as well as qualitative and quantitative assessment of groundwater resources and hydrogeological conditions;

- visualization of geological, hydrogeological and geophysical data and processes using GIS technology;

- consulting, studies and supporting vactivities in the field of environmental and power engineering based on mine water under various hydrogeological conditions.

Our staff has high qualifications confirmed by geological qualifications granted by the Minister of the Environment and the President of the WUG, as well as the WUG expert’s qualifications in the field of water hazard assessment. We have original methods for forecasting mine flooding processes, investigating the properties of rock and rock debris and modern measuring equipment.

We carry out the mentioned below test and measurements:

- rock permeability / filtration coefficient of any length of core (using the only one in Poland non-destructive permeameter PDPK400),

- microporosity, size and distribution of pores, surface area of rocks, dust, powders, zeolites, etc. (using the ASAP 2020 surface area analyzer),

- the actual density and open porosity of regular and irregular samples, both rocks and powders (using the AccuPyc II 1340 high pressure helium pycnometer).

Laboratory carries out research and service-related works regarding:

- scientific reports related to coal dust explosion hazards in mines, including research qualifying coal seams, functional chambers areas, coal storage areas, etc. as for their coal dust explosion hazards,

- tests on coal dust explosion hazard in rock workings, rock-coal workings and coal workings,

- tests on coal dust explosion hazard and matching necessary protection for the explosives storage, coal storage and other areas particularly subject to coal dust explosion hazards,

- assessment of the need to use main explosion-proof barriers to protect the ventilation areas (especially in the pit bottoms),

- assessment of the effectiveness in limiting dispersibility of the coal dusts using liquid and solid dampers as for coal dust counter-explosive prevention,

- assessment of the effectiveness in limiting volatility of the coal dusts using calcium chloride or magnesium chloride with surface-active agent additive,

- assessment of fire-explosion hazard in mechanical coal processing plants,

- tests on the effectiveness of safeguards against dusts explosion initiation and spreading,

- assessment of the factors influencing the possibility of dust initiation and spreading in tested facilities and spaces of the industrial plants,

- creating a schedule of dust deposits removal in:

- mechanical coal processing plants,

- power plants,

- mills,

- heat plants,

- CHP plants,

- coal desulphurisation plants,

- other industrial plants

- measurement of dust subsidence intensity,

- determination of quantity of dust remaining in the workings of the mine as well as in the facilities, levels and spaces of industrial plants,

- laboratory analysis of dusts remaining in the workings of the mine according to Polish,

- demonstrations of experimental dust explosions and training activities,

- tests and assessment of rock properties as for its sparking tendency which could ignite methane while operating the shearer in the mines,

- tests and assessment of materials properties as for its sparking tendency in the facilities and spaces of industrial plants with explosion hazard of gases and vapours of flammable liquids.

The staff employed in the Lab of Ecological Analyses have knowledge supported by high qualifications and many years of experience. The team consists of specialists in geology, hydrogeology, physics, and environmental protection, having the powers of experts from the list of the Silesian Voivode in the field of nature protection, preparing environmental impact assessments, as well as the powers of the Minister of the Environment in the field of hydrogeology.

The Lab of Ecological Analyses carries out fieldwork consisting of, among others, collecting environmental samples, testing the flow of watercourses and surface soil filtration coefficients, testing the slope stability. Sampling and transport of samples are carried out throughout Poland. A team of experienced staff collecting samples has the specialized equipment, which guarantees high quality of services provided in all field conditions.

The Lab of Ecological Analyses offers to monitor, in accordance with Polish law, of:

- ground and surface waters, as well as sewage,

- industrial, urbanized, agricultural and forest areas,

- landfills,

- mining waste disposal facilities,

- municipal and industrial sewage treatment plants,

- municipal sewage sludge and agricultural soils.

Division of Ecological Researches prepares a number of assessments, expertise, and opinions.

We guarantee participation and assistance in the process of obtaining administrative decisions resulting from legislation.

Division of Ecological Researches uses modern equipment for field testing and modern software to interpret and visualize the measurement results.

- Gas content research, including determination of methane content in coal seams;

- Simulations and analyses of methane content distribution in the coal seams,

Example of simulatons methane content distribution in the coal seams

(in cooperation with Department of Geology and Geophysics, PETREL software)

- Forecasting the emission of methane to operation, preparatory and development workings;

- Opinions on the classification of coal seams or their parts and the methane areas to the appropriate methane as well as gas and rocks outburst hazard categories;

- Classification of mining workings (rooms) to the appropriate degree of danger of methane explosion;

- Assessment of methane hazard development for operated longwalls taking into account the methane-ventilation conditions and the applied prevention including methane drainage;

- Development of technologies for methane recovery from coal deposits and its utilization;

- Research on the hazard of methane and rock outbursts in the coal seams or their parts in terms of the classification and the determination of the limits of the classification to the appropriate outburst hazard category as well as overcoming this hazard;

- Expertise on the methods of methane drainage in the operation areas;

- Designing of separate ventilation systems for the roadways developed in methane coal seams;

- Comprehensive methane and endogenous fires hazards assessment in the designed operation areas;

- Performing the pictures of potential ventilation grids of the coal mine,

- Computer characteristics of coalmines’ ventilation grid Ventgraph software,

Spatial graph of coal mine „S” ventilation grid in Ventgraph software

- numerical calculations (3D) of forecasted air flow as well as methane and coal dust contents in underground workings ventilation air.

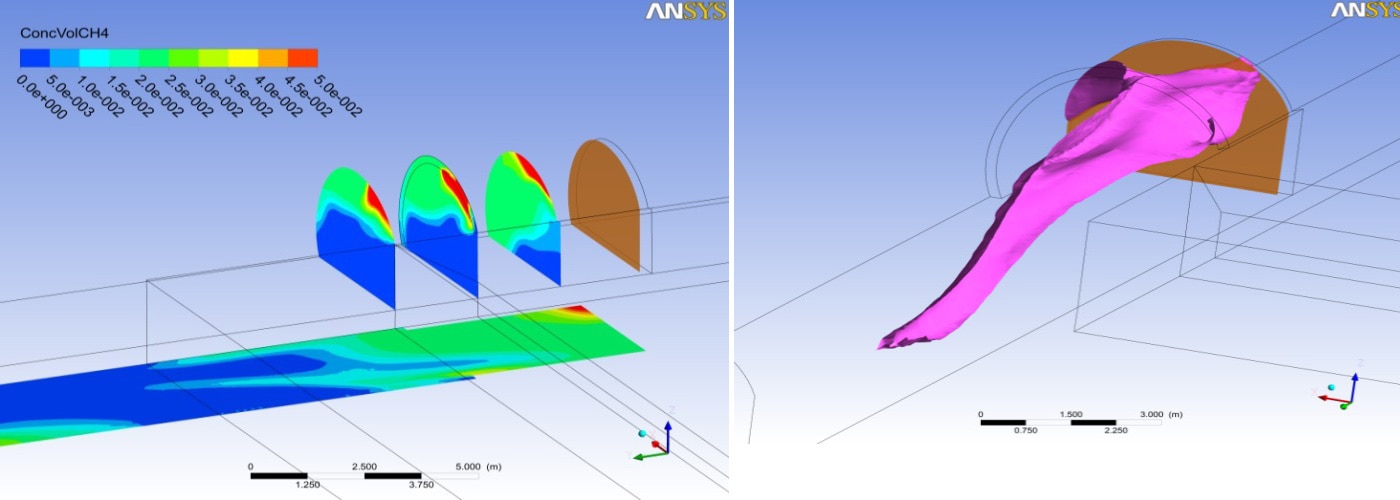

Forecasts of methane concentration distribution at the outlet from

the longwall („U” type ventilation method) with ventilation

compartment (based on CFD calculations in software AnSys CFX)

Forecast of methane content at the outlet from the longwall

(„U” type ventilation method) where the auxiliary ventilation

equipment was not used (CFD calculations, software: AnSys CFX)

Forecasts of methane concentration distribution at the outlet from

he longwall („U” type ventilation method) with auxiliary air tubing

(based on CFD calculations in software AnSys CFX)

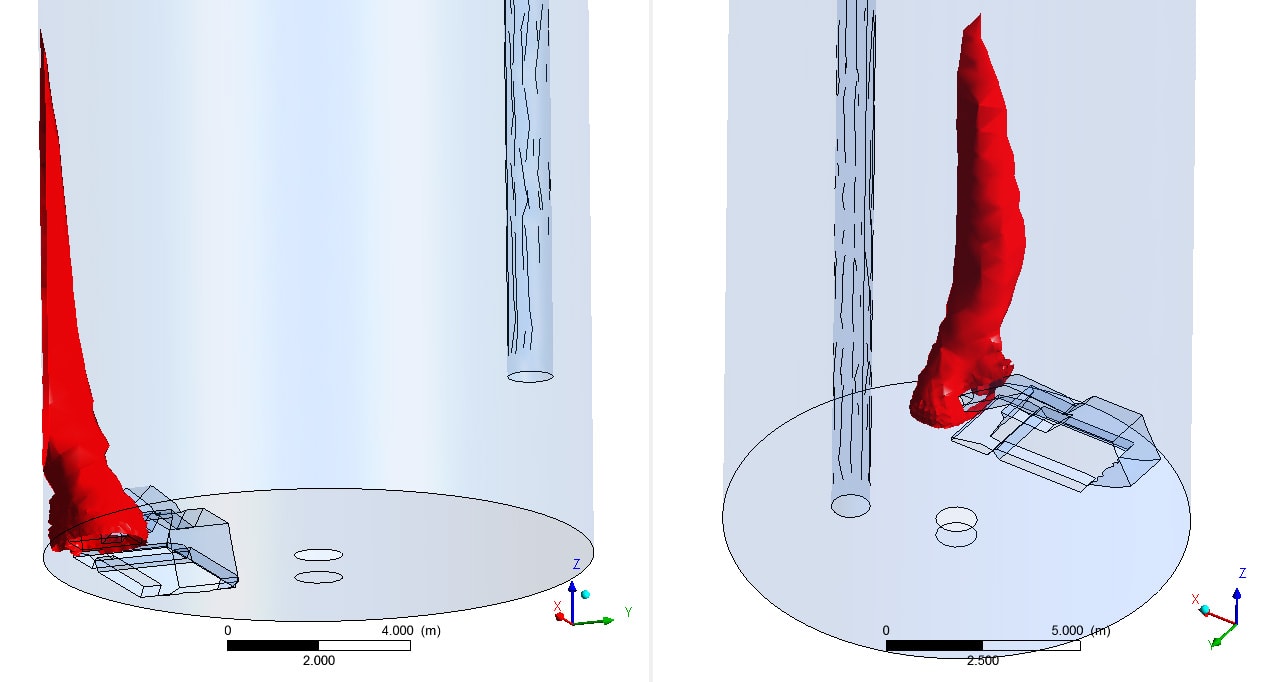

Forecast of methane (concentration of 3% v/v) zone distribution

in dredged retential reservoir – using the shearer

- Numerical calculations together with ventilation network analysis of designed areas of operation in the conditions of methane and endogenous fires hazard occurrence;

- Numerical calculations and design of the operation for the areas below the opening level;

- Research and assessment of the gas hazard for the subsequent stages of excluding the workings, areas, levels and shafts from the mining operation of a liquidated mine;

- Variant analysis of the simplification of the ventilation network model of the liquidated methane mine;

- Development of insulation technologies of the excavations in liquidated gassy mine;

- Developing of accumulated balance of free methane in the workings of liquidated coal mine in a conventionally accepted period of time in conjunction with hydrogeology, tectonics and the conditions related to the adjacent mines;

- Forecast of the possibility of gas hazard occurrence on the surface of liquidated gassy coal mine within mining area;

- Research on the kinetics and intensity of the mining gases inflow to the subsurface zone in the mining area of liquidated coal mine;

- Developing methods of active countermeasures for gas hazard in the subsurface zones in post-mining areas of liquidated coal mines.

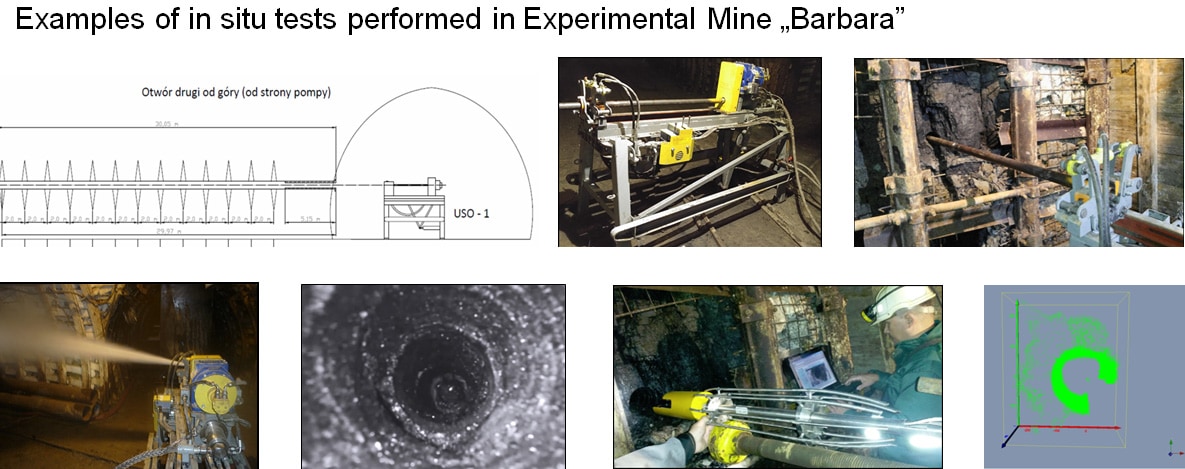

- Elaboration of the coal seam stimulation technique in order to increase its permeability and pre-drainage (hydroslotting), supporting CBM

Hydroslotting in the coal seam (in cooperation with Department

of Underground Research and Surface Maintenance and with

Department of Rock Bursts and Rock Mechanics) – GasDrain Project

- Elaboration of the outburst hazard forecasting for newly developed and poorly recognized parts of deposits/coal seams,

- Conducting in-situ measurements of basic outburst hazard coefficients applied in the coal mines i.e. methane desorption intensity, methane content, volume of the coal cuttings from the borehole and conciseness, in order to evaluate present outburst hazard or evaluating present forecast,

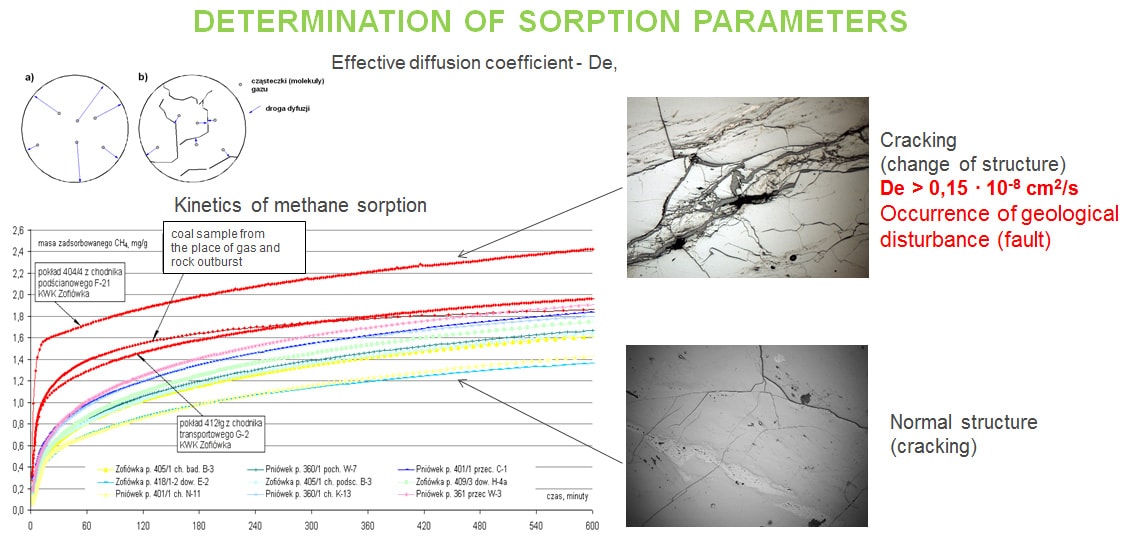

- Conducting comprehensive research of the coal seam (rocks) in order to determine its outburst proneness, covering extended measurements of so called sorption abilities - i.e. desorption kinetics and diffusion coefficient,

Coal sorption parameters tests to determine structural changes

- Deliver the opinion concerning technical projects of mining works conducted in the conditions of outburst hazard as well as designing of the deposit (coal seam), including ventilation system and protection in the a.m. hazardous conditions,

- Determination of the coal seam parameters classifying it into certain outburst’s hazard category and issuing the opinion concerning possibility of excluding part of the coal seam from its borders (so far) classifying into certain outburst category hazard,

- Evaluation of the outburst prevention efficiency applied in the coal mines and elaborating preventive treatment (rules) how to perform certain mining works in the zones of increased hazard.

- Sorption isotherms tests to determine deposit pressures and coal seam outbursts predispositions (occurrence of gas-dynamic phenomena)

Sorption isotherms tests on gravimetric setting IGA-001

- Determination of exploitation drainage degassing zones in subject coal seam and simulation of secondary methane content distribution in re outburst hazard forecasts and opinions

- Methane content and gas deposit pressures simulations in the coal seam,

- Analysis of outburst hazard basic parameters i.e. methane desorption intensity, coal density and geological disturbances’ evaluation (fault zones) impact on geo-technical parameters of the coal seam

- design of the support of roadway connections,

- design of large-size roadway support (functional, chamber),

- evaluation of the state of the roadway supports,

- evaluation of the degree of corrosion of the support and estimating the load bearing capacity of the corroded support,

- design and optimization of supports (arches, shackles and accessories) used in specific conditions,

- sesign and selection of supports for opening and preparatory excavations (drifts, longwall cross-cuts, main gates, ramps, dip headings),

- design and selection of shotcrete supports.

- project of cutting a coal deposit batch with all natural hazards taken into account,

- assessment of effective and economical extraction of a hard coal deposit with a longwall or alternative system,

- preparation of due diligence technical and environmental reports,

- design and selection of support reinforcement, adapted to the conditions occurring in underground mines,

- selection of shield and individual support for the mining-geological conditions of longwall mining,

- determination of the interaction capabilities of different types of supports in one longwall working,

- defining the conditions of work of the shield support in areas of rock burst hazard occurrence,

- evaluation of the degree of the caving gobs reconsolidation and the determination of the conditions of the operation of layers residing beneath,

- forecasting the convergence and loading of gateroads,

- design and selection of chock and rock bolt support and independent rock bolt support,

- design and selection of maintenance methods for galleries located within the mining face,

- introscope tests of drilling holes,

- in situ tests of rock mass strength with a hydraulic penetrometer,

- modelling the impact of underground mining on the stability of slopes and embankments,

- trainings, instructions, lectures on the correctness of roof management in caving longwalls and cooperation between the roof and longwall support with the rock mass.

- design of methods of liquidating shafts in different mining conditions; design of the technology of securing deposits in liquidated mines,

- selection and optimization of the construction of roadside packs,

- strength analysis of constructions used in the mining industry,

- and special supports,

- studies on the technical condition of vertical workings using video techniques,

- studies of the technical condition of vertical workings using rope access techniques (climbing techniques),

- examination of the quality of the bonding (bonding continuity) of mining anchors with non-destructive methods,

- design and selection of historic excavations and buildings,

- design of shaft and pit support.

- Legal and environmental analyses and expert opinions concerning the conditions for the use of waters (including legal surveys)

- Quantitative and qualitative modelling and balancing of ground and surface waters

- Hydrochemical phenomenon modelling

- Systemic solutions for rainwater management

- Water resource management planning in the context of catchment areas (Water Framework Directive and Floods Directive)

- Hydrological phenomenon modelling

- Strategic and program-scale reviews at national, regional and local scale (including development strategies, environmental protection programs, local revitalisation programs)

- Analyses of socio-economic, spatial and environmental issues with the use of scenario analysis and foresight

- Environmental risk analysis

- Rainwater management planning in cities and functional urban areas

- Environmental analyses for the purposes of adapting cities to climate change

- Historically contaminated land stocktaking

- Stocktaking and valorisation of urban blue-green infrastructure resources

- Forecasting the environmental impact of projects, plans, programs and strategies

- Natural stocktaking and valorisation

- Natural monitoring of terrains subjected to anthropogenic impact, including the effects of mining activity

- Planning urban river valley protection and revitalisation, including river restoration, riparian zone management and hydromorphological assessment

- GIS in environmental engineering and environmental management

- Preparing digital models and scenarios linking the environmental and spatial aspects

- Mobile platforms for measurement and analysis with the use of drones

- Spatial databases for the environment

- Implementing eco-innovations and assessing the eco-efficiency of technological solutions

- Preparing application materials in the field of urban and environmental engineering (applications, feasibility studies, business plans)

- Analyses and assessments of the economic and ecological effectiveness of investments for the purposes of institutions providing loans and credits (including financial analyses, CBA, MCA, DGC)

- Program-scale reviews at local, regional and national scale, related but not limited to development strategies

- Complex services within the scope of obtaining administrative decisions, encompassing the preparation of required documents as well as social and institutional consulting

- Water treatment and conditioning technologies for the purposes of human consumption and industry

- Modelling water supply and sewage systems

- Technologies for the treatment of municipal and industrial waste, including the modelling of biological waste treatment systems, membrane technologies

- Optimising existing technological solutions and intensifying waste treatment processes

- Assessing the efficiency of water and sewage management (including technical concepts and agglomeration plans)

- Developing technical and technological solutions at laboratory and pilot plant scale

- Technological innovations for the utilisation of waste sludge for the purposes of the natural environment, energy and others

- Intensifying sludge processing in waste treatment plants

- Technical and economic analyses of solutions in the context of waste sludge

- Environmental and legal analyses and expert opinions in the context of waste sludge management

- Elaboration of the outburst hazard forecasting for newly developed and poorly recognized parts of deposits/coal seams,

- Conducting in-situ measurements of basic outburst hazard coefficients applied in the coal mines i.e. methane desorption intensity, methane content, volume of the coal cuttings from the borehole and conciseness, in order to evaluate present outburst hazard or evaluating present forecast,

- Conducting comprehensive research of the coal seam (rocks) in order to determine its outburst proneness, covering extended measurements of so called sorption abilities - i.e. desorption kinetics and diffusion coefficient,

Coal sorption parameters tests to determine structural changes

- Deliver the opinion concerning technical projects of mining works conducted in the conditions of outburst hazard as well as designing of the deposit (coal seam), including ventilation system and protection in the a.m. hazardous conditions,

- Determination of the coal seam parameters classifying it into certain outburst’s hazard category and issuing the opinion concerning possibility of excluding part of the coal seam from its borders (so far) classifying into certain outburst category hazard,

- Evaluation of the outburst prevention efficiency applied in the coal mines and elaborating preventive treatment (rules) how to perform certain mining works in the zones of increased hazard.

- Sorption isotherms tests to determine deposit pressures and coal seam outbursts predispositions (occurrence of gas-dynamic phenomena)

Sorption isotherms tests on gravimetric setting IGA-001

- Determination of exploitation drainage degassing zones in subject coal seam and simulation of secondary methane content distribution in re outburst hazard forecasts and opinions

- Methane content and gas deposit pressures simulations in the coal seam,

- Analysis of outburst hazard basic parameters i.e. methane desorption intensity, coal density and geological disturbances’ evaluation (fault zones) impact on geo-technical parameters of the coal seam